PVC Pipe Inch

![]()

Explore the world of PVC Pipe with our specialised PVCu pressure pipes category, designed to provide top-notch solutions for a broad array of applications. Our extensive selection of PVC Pipes meets the demands of various sectors, including water treatment, HVAC systems, chemical processing, industrial fluid transport, effluent management and transportation of potable water (drinking water). With a variety of PVC Pipe sizes and pressure classes available, we are committed to delivering the exact specifications your project requires.

Our PVC Pipe Range

We provide PVCu pressure pipes in sizes ranging from 1/2" to 8", catering to a broad spectrum of requirements. Our PVC pipe is available in four main classes to suit different pressure needs:

Class C (9 Bar): Ideal for lower pressure applications, ensuring durability and reliability.

Class D (12 Bar): Offers a balance between strength and flexibility for medium pressure systems.

Class E (15 Bar): Designed for high-pressure applications, providing maximum durability.

Class 7 (12 Bar): Larger average wall thickness and commonly used for threaded applications.

Whether for domestic or industrial applications, our PVC pipes are trusted for their high quality and performance. Available in lengths of 3m and 6m, our pipes provide versatility and ease of installation, ensuring you have the right fit for your system's specifications.

What is the difference between PVC, PVCu, and uPVC?

PVCu and uPVC are exactly the same and, in our industry, are often shortened to just PVC.

How do you cut PVC pipe?

Cutting PVC pipe accurately and efficiently requires the right tools and techniques. Here's a step-by-step guide on how to cut PVC pipe, ensuring a clean and precise cut:

- Select the Right Tool: For most PVC sizes, a ratchet or rotary pipe cutter is ideal as it gives a clean, square cut. For larger diameter pipes, you can use the Nerrad Professional Wheel Pipe Cutter or alternatively, you might need to use a fine-toothed saw, such as a hacksaw or a handsaw specifically designed for cutting PVC.

- Measure and Mark the Pipe: Measure the length you need to cut and use a marker to draw a straight line around the pipe. This serves as a guide to ensure your cut is straight.

-

Secure the Pipe: Before cutting, make sure the pipe is secured in place. You can use a vice or clamp to hold it steady, ensuring it doesn't move while you're cutting.

- Make the Cut: We recommend using a ratchet or rotary style cutter.

- Deburr the Pipe: After cutting, there will likely be some burrs or rough edges inside and around the cut end of the pipe. Use a deburring tool to smooth these out. This is important for a good fit when connecting pieces and for safety.

- Clean the Cut: Wipe the cut end with a clean rag to remove any PVC dust or debris. This is especially important if you're going to be glueing the pipe, as debris can interfere with the adhesive.

- Check the Fit: If the cut pipe is meant to connect to another piece, check the fit before proceeding with your project. The pipe should fit snugly without forcing.

Safety Tips:

- Always wear safety goggles to protect your eyes from PVC shavings or dust.

- Wear gloves to protect your hands while cutting and deburring.

- Work in a well-ventilated area to avoid inhaling PVC dust.

- By following these steps, you can achieve a clean, straight cut on PVC pipe, which is essential for a successful PVC piping project.

How do you Prepare and Glue PVC Pipe?

Creating strong and lasting joints in PVC piping systems involves precise preparation and application of solvent cement. Below is a comprehensive guide detailing how to prepare and glue PVC pipe effectively, ensuring robust and leak-proof connections:

-

Cutting the Pipe:

-

First, measure the length of the PVC pipe you need and mark where you'll make your cut. Use a PVC cutter to cut the pipe.

-

Ensure the cut is straight and clean without any burrs. If there are any rough edges, remove them with a deburring tool.

-

- Chamfering and Marking:

-

Chamfer the leading edge of the pipe at approximately 30° to 40°. This chamfer aids in preventing solvent cement from being wiped off when joining and helps form a solvent ring at the chamfer, enhancing the seal.

-

Mark the pipe from the chamfered end back to a length equal to the socket depth plus 5mm. This mark will serve as a visual indicator ensuring the pipe is fully inserted during joining.

-

- Cleaning and Roughening:

-

Clean both the pipe's outer surface (up to the marked line) and the fitting's inner surface using a lint-free cloth or paper towels dampened with cleaning fluid.

-

Roughen these surfaces with abrasive cloth or paper to enhance adhesive contact. Ensure not to increase the clearance significantly.

-

- Applying Solvent Cement:

-

After cleaning and allowing the surfaces to dry, apply PVC solvent cement evenly without using excess. All surfaces to be joined should be covered with cement.

-

In temperatures between 5 - 25°C, quickly join the components while the cement is wet, typically within 3 minutes, depending on ambient conditions.

-

- Joining and Holding:

-

Insert the pipe into the PVC fitting without twisting, ensuring alignment and full engagement, indicated by the alignment of the mark with the socket edge.

-

Hold the assembly firmly for a specified duration based on the pipe size to ensure proper bonding.

-

- Curing and Ventilation:

-

After making the joint, avoid disturbing it for at least 10 - 15 minutes to maintain weld integrity. Proper ventilation is crucial during curing.

-

For pipes up to 8", a curing time of 8 hours is needed for the joint to withstand working pressure, with 24 hours recommended before pressure testing.

-

- Safety and Environmental Controls:

-

Always ensure adequate ventilation due to the hazardous vapours from the solvent cement.

-

Follow all safety guidelines for handling and applying solvent cement, including wearing appropriate personal protective equipment.

-

- Post-Jointing Checks:

-

Once the joint is made, a bead of cement should form an O-ring between the pipe chamfer and the socket's internal wall, ensuring a proper seal. Any excess cement should be wiped off to leave a clean joint.

-

By adhering to these detailed steps, you can achieve durable and reliable joints in your PVC piping systems, ensuring optimal performance and longevity.

-

Please note: This is a brief overview of the joining process. Consult the manufacturer's guide for full instructions.

| Pipe Size (inches) | Holding Time |

| ¾" - 2" | 30 seconds |

| 2 ½" - 4" | 45 seconds |

| 5" - 8" | 1 minute |

| 10" - 12" | 2 minutes |

What Is The Difference Between ABS & PVC Pipe?

ABS (Acrylonitrile Butadiene Styrene) and PVCu (Polyvinyl Chloride Unplasticised) pipes are both widely used in plumbing and piping applications but have distinct differences in their composition, properties, and applications. Here's a detailed comparison:

- Material Composition:

ABS: It's a thermoplastic polymer made from acrylonitrile, butadiene, and styrene. ABS is known for its toughness and impact resistance.

PVC: This is also a thermoplastic polymer, but it's made from unplasticised polyvinyl chloride. PVC is known for its durability, high chemical resistance, and excellent corrosion resistance.

- Colour:

ABS: Typically light grey, which helps in distinguishing it from PVC pipe.

PVC: Dark grey.

- Temperature Resistance:

ABS: Has better resistance to cold temperatures and can maintain its impact resistance and toughness at lower temperatures.

PVC: Has a higher resistance to high temperatures compared to ABS.

- Chemical Resistance:

Both materials have good chemical resistance, but PVC generally offers better resistance to a broader range of chemicals, making it more suitable for industrial applications involving corrosive substances. - Applications:

ABS: Commonly used for drain, waste, and vent pipes, especially in residential buildings. It's also used in automotive and appliance applications due to its toughness.

PVC: Extensively used in both potable water supply lines and sewage systems. PVC's non-toxicity and chemical resistance make it suitable for a wide range of applications, including medical, construction, and food-related industries.

- Installation and Joining:

Both ABS and PVC pipes are joined using solvent cement, but the specific type of cement differs due to their distinct chemical compositions. It's crucial to use the right solvent cement corresponding to the pipe material. - Code Compliance and Usage:

Building codes in some regions or specific applications may dictate the type of pipe that must be used. For instance, some local codes do not allow ABS in certain types of construction. - UV Resistance:

PVC has better resistance to UV light, making it more suitable for outdoor applications unless ABS is specifically treated for UV protection.

When choosing between ABS and PVC, it's essential to consider the specific requirements of your application, including code compliance, temperature conditions, exposure to chemicals, and the intended use. Both materials have their advantages and ideal use cases, so the choice should be based on the specific needs of your project.

Is PVC Pipe Suitable For Drinking Water?

Yes. Our PVCu pipes are WRAS approved, which means they have been tested and certified to meet strict standards for contact with potable water. This approval assures that the pipes do not contaminate the water, maintaining its quality and safety for consumption.

PVCu's inherent properties ensure that it does not impart any odour or taste to the water, a critical factor for maintaining the water's purity and drinkability.

How To Measure Imperial PVC Pipe

Measuring PVC pipe correctly is crucial for ensuring that the pipe fits appropriately with connectors, fittings, and other components of a plumbing system. Here's how you can accurately measure PVC pipe:

Nominal Size:

PVC pipe sizes are often expressed in terms of nominal size, which is a standardised convention that approximates the pipe's inner diameter. For example, a 1-inch nominal size PVC pipe doesn't actually measure 1 inch either in ID or OD; its OD is closer to 1.315 inches. Refer to the PVC pipe size chart (on the product page) if you have the OD and need to find the corresponding nominal size. This can be especially useful for matching the pipe with the correct fittings.

Determining the Outside Diameter (OD):

Use a measuring tape or ruler to measure across the centre of the pipe's end from one outer edge to the other. This measurement is the outside diameter, which is often how PVC pipe is categorised.

Wall Thickness:

Measure the wall thickness using a caliper. Place one end of the caliper on the outer edge and the other on the inner edge to get the wall thickness. Knowing the wall thickness is essential for identifying the pipe's pressure capacity.

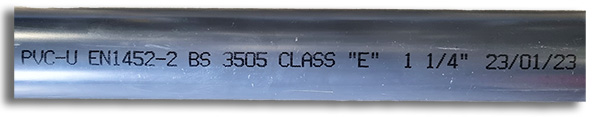

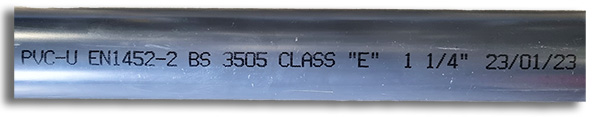

Understanding the Markings:

Most PVC pipes have printing on the exterior that provides information about the diameter and other technical information. These markings can give you a quick reference without needing to measure.

Using the above as an example, let's break down the markings on the pipe:

- Material: PVC-U

- Standards: EN1452-2, BS 3505

- Variation Of Pipe: Class “E”

- Size: 1 ¼”

- Date Of Manufacture: 23/01/23

Using the Right Tools:

For external measurements, a flexible measuring tape or ruler works well. For more precise measurements, especially the wall thickness, a caliper is the best tool.

When purchasing new PVC pipe or fittings, the most critical measurement is the nominal size, as this is typically how they are classified and sold. For repairs or modifications to existing systems, more detailed measurements might be necessary to ensure compatibility and a proper fit.

PVC Pipe Imperial Operating Temperature & Pressure Rating

PVC Pipe Class C - 9 Bar

| Product Code | Nominal Size (inch) | Average Outside Diameter (mm) | Average Bore Inside Diameter (mm) | Average Wall Thickness (mm) | Length (m) | Weight (kg) |

| 356632 | 2 | 60.3 | 54.7 | 2.8 | 3 | 2.98 |

| 356631 | 2 | 60.3 | 54.7 | 2.8 | 6 | 5.95 |

| 359395 | 2.5 | 75.2 | 68.8 | 3.2 | 3 | 4.95 |

| 359394 | 2.5 | 75.2 | 68.8 | 3.2 | 6 | 9.89 |

| 356634 | 3 | 88.9 | 81.3 | 3.8 | 3 | 6 |

| 356633 | 3 | 88.9 | 81.3 | 3.8 | 6 | 12 |

| 356636 | 4 | 114.3 | 104.6 | 4.9 | 3 | 8.15 |

| 356635 | 4 | 114.3 | 104.6 | 4.9 | 6 | 16.3 |

| 356638 | 5 | 140.2 | 128.3 | 6 | 3 | 12.21 |

| 356637 | 5 | 140.2 | 128.3 | 6 | 6 | 24.42 |

| 356640 | 6 | 168.3 | 154.1 | 7.1 | 3 | 17.49 |

| 356639 | 6 | 168.3 | 154.1 | 7.1 | 6 | 34.98 |

| 359753 | 8 | 219.1 | 202.3 | 8.4 | 3 | 34.35 |

| 356641 | 8 | 219.1 | 202.3 | 8.4 | 6 | 68.7 |

| Temperature to Pressure Relationship | |

| Temperature (°C) | Maximum Pressure (bar) |

| 0 | 9 |

| 20 | 9 |

| 30 | 8.1 |

| 40 | 6.3 |

| 50 | 4 |

| 60 | 1.3 |

PVC Pipe Class D - 12 Bar

| Product Code | Nominal Size (inch) | Average Outside Diameter (mm) | Average Bore Inside Diameter (mm) | Average Wall Thickness (mm) | Length (m) | Weight (kg) |

| 356643 | 1.25 | 42.2 | 37.2 | 2.5 | 3 | 1.76 |

| 356642 | 1.25 | 42.2 | 37.2 | 2.5 | 6 | 3.51 |

| 356645 | 1.5 | 48.2 | 42.6 | 2.8 | 3 | 2.31 |

| 356644 | 1.5 | 48.2 | 42.6 | 2.8 | 6 | 4.62 |

| 356647 | 2 | 60.3 | 53.5 | 3.4 | 3 | 3.59 |

| 356646 | 2 | 60.3 | 53.5 | 3.4 | 6 | 7.18 |

| 356649 | 3 | 88.9 | 78.9 | 5 | 3 | 7.7 |

| 356648 | 3 | 88.9 | 78.9 | 5 | 6 | 15.4 |

| 356651 | 4 | 114.3 | 101.3 | 6.5 | 3 | 10.66 |

| 356650 | 4 | 114.3 | 101.3 | 6.5 | 6 | 21.31 |

| 356655 | 6 | 168.3 | 149.3 | 9.5 | 3 | 22.9 |

| 356654 | 6 | 168.3 | 149.3 | 9.5 | 6 | 45.8 |

| Temperature to Pressure Relationship | |

| Temperature (°C) | Maximum Pressure (bar) |

| 0 | 12.0 |

| 20 | 12.0 |

| 30 | 10.8 |

| 40 | 8.4 |

| 50 | 5.4 |

| 60 | 1.8 |

PVC Pipe Class E - 15 Bar

| Product Code | Nominal Size (inch) | Average Outside Diameter (mm) | Average Bore Inside Diameter (mm) | Average Wall Thickness (mm) | Length (m) | Weight (kg) |

| 356658 | 1/2 | 21.3 | 17.5 | 1.9 | 3 | 0.68 |

| 356657 | 1/2 | 21.3 | 17.5 | 1.9 | 6 | 1.35 |

| 356660 | 3/4 | 26.8 | 22.4 | 2.2 | 3 | 0.96 |

| 356659 | 3/4 | 26.8 | 22.4 | 2.2 | 6 | 1.91 |

| 356662 | 1 | 33.6 | 28.6 | 2.5 | 3 | 1.37 |

| 356661 | 1 | 33.6 | 28.6 | 2.5 | 6 | 2.73 |

| 356664 | 1 1/4 | 42.2 | 36.2 | 3 | 3 | 2.15 |

| 356663 | 1 1/4 | 42.2 | 36.2 | 3 | 6 | 4.3 |

| 356666 | 1 1/2 | 48.2 | 41.4 | 3.4 | 3 | 2.78 |

| 356665 | 1 1/2 | 48.2 | 41.4 | 3.4 | 6 | 5.56 |

| 356668 | 2 | 60.3 | 51.9 | 4.2 | 3 | 4.39 |

| 356667 | 2 | 60.3 | 51.9 | 4.2 | 6 | 8.77 |

| 359397 | 2 1/2 | 75.2 | 65.4 | 4.9 | 3 | 7.36 |

| 359396 | 2 1/2 | 75.2 | 65.4 | 4.9 | 6 | 14.71 |

| 356670 | 3 | 88.9 | 76.5 | 6.2 | 3 | 9.4 |

| 356669 | 3 | 88.9 | 76.5 | 6.2 | 6 | 18.8 |

| 356672 | 4 | 114.3 | 98.5 | 7.9 | 3 | 12.74 |

| 356671 | 4 | 114.3 | 98.5 | 7.9 | 6 | 25.47 |

| 356674 | 6 | 168.3 | 144.9 | 11.7 | 3 | 30.89 |

| 356673 | 6 | 168.3 | 144.9 | 11.7 | 6 | 61.77 |

| Temperature to Pressure Relationship | |

| Temperature (°C) | Maximum Pressure (bar) |

| 0 | 15 |

| 20 | 15 |

| 30 | 13.5 |

| 40 | 10.5 |

| 50 | 6.7 |

| 60 | 2.2 |

PVC Pipe Class 7 - 12 Bar

| Product Code | Nominal Size (inch) | Average Outside Diameter (mm) | Average Bore Inside Diameter (mm) | Average Wall Thickness (mm) | Length (m) | Weight (kg) |

| 383231 | 1/2 | 21.3 | 13.3 | 4 | 3 | 1.28 |

| 383230 | 1/2 | 21.3 | 13.3 | 4 | 6 | 2.55 |

| 383233 | 3/4 | 26.8 | 18.6 | 4.1 | 3 | 1.76 |

| 383232 | 3/4 | 26.8 | 18.6 | 4.1 | 6 | 3.51 |

| 383235 | 1 | 33.6 | 23.8 | 4.9 | 3 | 2.55 |

| 383234 | 1 | 33.6 | 23.8 | 4.9 | 6 | 5.1 |

| 383237 | 1 1/4 | 42.2 | 31.8 | 5.2 | 3 | 3.55 |

| 383236 | 1 1/4 | 42.2 | 31.8 | 5.2 | 6 | 7.1 |

| 383239 | 1 1/2 | 48.2 | 37.2 | 5.5 | 3 | 4.35 |

| 383238 | 1 1/2 | 48.2 | 37.2 | 5.5 | 6 | 8.69 |

| 383241 | 2 | 60.3 | 48.5 | 5.9 | 3 | 6.1 |

| 383240 | 2 | 60.3 | 48.5 | 5.9 | 6 | 12.2 |

PVC Chemical Compatibility Guide

If you require any further information, our excellent customer service team is here to help so please call us on 01794 835835.

Our PVCu pressure pipe is available in sizes 1/2" to 8" in classes C, D, E and 7.

As a material, polyvinyl chloride - unplasticised has a wide temperature and pressure range, coupled with great chemical resistance, meaning it can be relied upon in a number of applications, such as water treatment, heating, cooling, chemical and industrial fluid handling, and effluent treatment. As PVC is odourless and tasteless, it is also ideal for transporting potable water (drinking water).

Imperial PVC pipe sizes are expressed by the nominal bore of the pipe, which is an approximation of the internal bore. In reality, a 3" PVC pipe will not measure 3" internally, for example. However, a class C 3" pipe will have exactly the same outer diameter as a class D 3" pipe, and the same as any other 3" PVC pipe. This is because the wall thickness of the pipe governs the pressure, and allows any 3" PVC pipe to fit in any 3" PVC pipe fitting.

For detailed data on PVC pipe sizes, please select the ‘More Info’ tab in the relevant pipe pages. If you have any queries on sizes, please do not hesitate to contact us. We'd much rather answer your questions and give advice before you commit to a purchase.

Approvals:

|

WRAS approved Approval number 2010508 |

Video - PVC vs ABS: What's the Difference?

Downloads:

PVC Chemical Compatibility General Guide

Frequently Asked Questions:

Q: What does PVCu stand for?

A: Polyvinyl chloride - unplasticised.

Q: What's the difference between PVC, PVCu and uPVC?

A: PVCu and uPVC are exactly the same and, in our industry, are often shortened to just PVC.

Q: How do you connect PVC pipe and fittings?

A: For plain ended fittings, PVC solvent cement is used for joining. For threaded fittings, it is recommended PTFE tape is used on the thread to create a more reliable joint.

Q: What's the difference between PVC and ABS?

A: Click here to see our extremely informative video which addresses this very subject.

If you require any further information, our excellent customer service team is here to help so please call us on 01794 835835.