Vulcathene

Introduction To Vulcathene Lab Drainage

Vulcathene lab drainage systems are the leading choice for chemical waste management in laboratories worldwide. Designed to meet the rigorous demands of modern scientific and educational facilities, Vulcathene offers unparalleled reliability and safety. With over 65 years of proven performance, this system is the gold standard for chemical waste drainage, ensuring the secure handling of aggressive chemicals, solvents, acids, and alkalis. Trusted by schools, universities, hospitals, and research facilities, Vulcathene continues to set the benchmark for laboratory drainage solutions.

Key Features Of Vulcathene

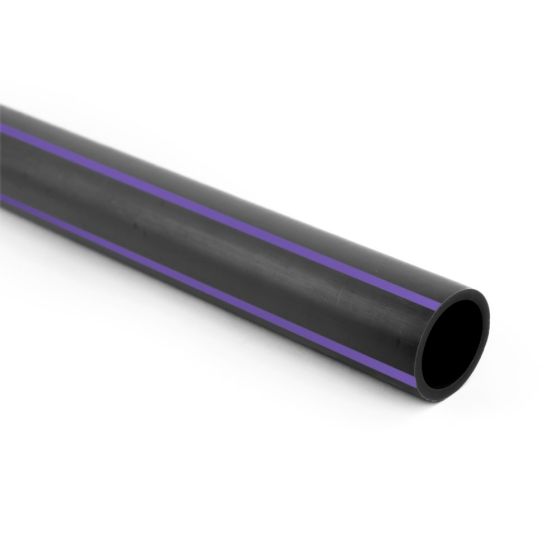

- Superior Chemical Resistance: Vulcathene systems are purpose-built to withstand the harshest chemical environments. Manufactured from co-polymer polypropylene with Carbon Black ultra-violet stabilizer, Vulcathene offers exceptional resistance to a wide range of aggressive chemicals, making it ideal for use in laboratories where safety and durability are paramount.

- Versatile Jointing Methods: Vulcathene provides two reliable jointing methods - Mechanical and Enfusion. The mechanical system features a unique nut and olive method that ensures simple and fast installation, while the Enfusion method uses electrofusion for a controlled, secure fit, perfect for applications where the pipe is buried or in ceiling voids.

- Comprehensive Product Range: The Vulcathene range includes pipes, waste outlets, sinks, drip cups, anti-siphon traps, and a variety of fittings from 38mm to 152mm. This extensive selection ensures that Vulcathene can meet the needs of any laboratory drainage system, providing flexibility and comprehensive solutions.

- Proven Reliability: With over six decades of use in laboratories around the world, Vulcathene has a track record of exceptional performance. Its ability to handle a wide variety of chemical combinations, including acids, alkalis, solvents, detergents, blood samples, and radioactive wastes, underscores its reliability and versatility.

- Safety and Compliance: Vulcathene systems are designed to meet the highest safety standards. The anti-siphon traps and borosilicate glass base traps are engineered to prevent backflow of hazardous fumes and provide visible identification and recovery of valuable solids. Vulcathene products are also British Board of Agrément approved, ensuring they meet stringent quality and safety requirements.

- Ease of Installation and Maintenance: Vulcathene’s design allows for quick and efficient installation with minimal tools. The mechanical joints can be easily made and remade without compromising their efficiency, enabling system changes at reduced costs. The enfusion fittings offer precise control of jointing, ensuring a secure and durable connection.

- Environmental and Quality Standards: All Vulcathene products are manufactured in accordance with BS EN ISO 9001 and ISO 14001, ensuring high quality and environmentally friendly production processes. This commitment to quality guarantees that every Vulcathene system delivers consistent, reliable performance.

Vulcathene Technical Specifications

Material Composition:

- Material: Co-polymer polypropylene with Carbon Black ultra-violet stabiliser

- Chemical Resistance: High resistance to a wide range of aggressive chemicals including acids, alkalis, solvents, detergents, blood samples, retroviruses, and radioactive wastes

Pipe Dimensions:

- Nominal Internal Diameters: 38mm, 51mm, 76mm, 102mm, 152mm

- Standard Lengths: 4m

Jointing Methods:

Mechanical Jointing:

- Method: Nut and olive technique

- Features: Demountable, simple and fast installation, can be remade without affecting joint efficiency

Enfusion Jointing:

- Method: Electrofusion using an integral resistance wire in fitting sockets

- Features: Controlled fusion for secure fit, ideal for buried or overhead pipes

Product Range:

- Pipes: Available in various diameters for different applications

- Waste Outlets: Including slotted and unslotted options

- Sinks: Robust design with self-draining bases

- Drip Cups: Steeply sloping sides and wide rims for stability

- Traps: Anti-siphon traps and borosilicate glass base traps

- Fittings: Bends, tees, couplers, reducers, adaptors, and access pipes

Performance Characteristics:

- Temperature Range: Operational between -20°C and +100°C

- Impact Strength: High impact strength to minimise damage during installation and use

- Abrasion Resistance: Smooth bore and high resistance to abrasion

Standards and Approvals:

- Quality Certification: BS EN ISO 9001

- Environmental Certification: ISO 14001

- British Board of Agrément: Approved (Certificate reference 24/7091)

Additional Features:

- Anti-Siphon Traps: Designed to prevent suction and ensure effective drainage

- Thermal Stress Relief Units: Available for managing thermal expansion and contraction

- Compatibility: Can be connected to other pipework systems using flexible couplings and adaptors

Installation Guide for Vulcathene Lab Drainage Systems

Below is a brief guide to installing Vulcathene lab drainage pipe and fittings. For full details please consult the manufacturer's guide.

Mechanical Fittings:

- Cutting the Pipe: Use a rotary plastic pipe cutter for a clean, square cut. Remove all burrs if a saw is used.

- Grooving the Pipe: Insert the pipe into the grooving tool and adjust the cutting blade to half depth. Rotate anti-clockwise, then adjust to full depth and repeat. Ensure the groove is clean and free from swarf.

- Assembling the Joint: Slide the nut and olive onto the pipe, seating the olive into the groove. Apply Vulcathene lubricant to the threads. Hand tighten the nut, then fully tighten with Vulcathene spanners.

Enfusion Fittings:

- Cutting and Preparing the Pipe: Use a rotary plastic pipe cutter for a clean, square cut. Scrape the pipe end to remove the oxidized layer.

- Setting Up the Enfusion Control Unit: Ensure the power source provides 104-126 volts at 45-65 cycles. Check the maximum number of joints per pipe size.

- Making the Joint: Fit the clamp over the hub of the socket and tighten. Connect the output leads from the welding machine to the fitting. Press the start button to begin the welding process. Allow the joint to cool for at least 5 minutes before removing clamps.

Additional Information:

- Pipe Falls: Ensure a fall of 2°-3° in horizontal waste runs for optimal flow.

- Support: Use Vulcathene pipe clips at recommended centres: 1.22m for 38mm, 1.37m for 51mm, 1.52m for 76mm, and 1.83m for 102mm and 152mm pipes.

- Buried Pipes: Bury pipes at least one metre deep with a 100mm bed of suitable pipe bedding.

- Thermal Movement: Install Vulcathene stress relief units (SRUs) on stacks at every floor level and on horizontal pipes as needed.

For detailed instructions, it's crucial to refer to the Vulcathene Installation Guide.

Connecting Vulcathene To Other Pipework

Vulcathene systems are highly versatile and can be connected to other types of pipework systems, ensuring seamless integration within various plumbing configurations. Here's how you can connect Vulcathene to different pipe materials:

Methods of Connection

- Flexible Couplings: Flexible couplings are used to join pipes of different materials and sizes. They provide a secure, leak-proof connection while accommodating slight differences in diameter.

- Installation: Select a suitable flexible coupling that fits both Vulcathene and the other pipe material (e.g., HDPE, PVC). Slide the coupling over the end of both pipes. Tighten the clamps on the coupling using a spanner to ensure a secure fit.

- Threaded and Flange Adaptors: These adaptors allow for the connection of Vulcathene pipes to threaded or flanged pipe systems.

- Installation: For threaded adaptors, ensure that the threads on both the adaptor and the connecting pipe are clean and free from debris. Apply a suitable thread sealant to the threads. Screw the adaptor onto the threaded pipe, then connect the Vulcathene pipe using the mechanical or enfusion jointing method. For flange adaptors, align the flanges of both pipes, insert a gasket between them, and bolt the flanges together.

- Polyfusion Adaptors: Polyfusion adaptors are specifically designed to connect Vulcathene to other plastic pipe systems, such as HDPE.

- Installation: Attach the polyfusion adaptor to the Vulcathene pipe using the appropriate jointing method. Insert the other plastic pipe into the adaptor and secure the connection as per the adaptor’s instructions.

Additional Information

- Compatibility: Ensure that all materials and fittings used are compatible with the substances being drained through the system.

- Support: Provide adequate support for both Vulcathene and the other pipe material to prevent stress on the joints.

- Consultation: If unsure about the compatibility or installation process, please get in contact or refer to the manufacturer’s guidelines for specific recommendations.

Downloads

If you require any further information, our excellent customer service team is here to help so please call us on 01794 835835.