Prevost Hose & Tube

Introduction

Prevost Air Hose & Tube systems are engineered to deliver reliability, flexibility, and durability across various industrial applications. Designed to withstand demanding conditions, these hoses and tubes ensure optimal performance in compressed air and fluid distribution systems. With a focus on safety and efficiency, Prevost products minimise obstructions, reduce maintenance efforts, and provide seamless connectivity.

Application

Prevost Air Hose & Tube systems are ideal for a wide range of industrial and commercial applications, including:

- Compressed Air Distribution – Efficiently delivers compressed air to tools and machinery.

- Pneumatic Systems – Ensures smooth operation of pneumatic equipment.

- Automotive & Manufacturing – Suitable for workshop air supply, assembly lines, and production environments.

- Fluid Transfer – Facilitates leak-free transportation of water, air, and other non-corrosive fluids.

- HVAC Systems – Used in air and ventilation installations.

Key Features & Benefits

- Compact & Lightweight – Facilitates easy handling and installation.

- Durable Construction – Built to withstand tough working environments.

- Optimised Flow Rates – Designed for efficient airflow and reduced pressure drops.

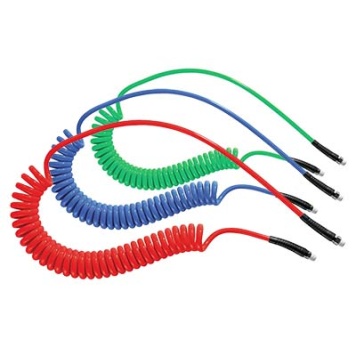

- Colour-Coded Options – Available in Blue, Red, and Green for easy identification in multi-line systems.

- Leak-Free System – Secure connections prevent air leaks, improving energy efficiency.

- Non-Interchangeable Design – Ensures compatibility within the Prevost range, preventing mismatched fittings.

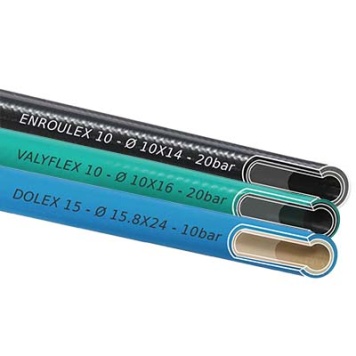

Technical specification

Material:

- Polyurethane Tube (PU)

- Polyamide Tube (PA)

- Maximum Pressure: 16 bar

Temperature Range:

- Polyurethane Tube: -15°C to +60°C

- Polyamide Tube: -40°C to +70°C

- Available Colours: Blue, Red, Green

Applications:

- Polyurethane Tube: Compressed air, pneumatic tools, fluid transfer

- Polyamide Tube: Industrial air, fluid, and vacuum systems

Installation Overview

- Preparation – Ensure the selected tube and fittings match the required specifications.

- Cutting & Deburring – Cut the hose to the required length and remove sharp edges.

- Fitting Selection – Use Prevost-approved fittings to maintain system integrity.

- Connection – Securely attach the tubing to the fittings using recommended tools.

- Testing – Pressurise the system and check for leaks or pressure drops.

- Maintenance – Regularly inspect for wear, ensuring consistent performance and longevity.

IMPORTANT: The technical data given on this website is for preliminary information purposes only and is published without guarantee. All line drawings are for illustrative purposes only and should not be regarded as wholly accurate in every detail. We reserve the right to withdraw or to alter the specification of any product without notice. For more information, please consult our Terms of Business.

If you require any further information, our excellent customer service team is here to help so please call us on 01794 835835.