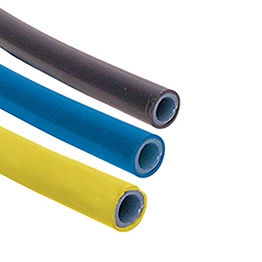

Tube

Our industrial tubing range covers a huge variety of materials, diameters and performance ratings, giving you dependable options for almost any pneumatic, fluid transfer, or process application. Whether you’re building compact air circuits, running long production lines, or looking for food-grade pipework, you’ll find a suitable tube here.

Each product is built for reliability, excellent chemical resistance and stable performance across demanding temperature and pressure conditions. From lightweight nylon to crystal-clear polyurethane, the range is designed to handle everything from compressed air to oils, water, gases, and industrial fluids.

What Is the Difference Between Hose and Tube?

Although the terms are often used interchangeably, hose and tube serve different purposes and are built differently.

Tube

- Rigid or semi-rigid construction

- Defined internal and external diameters for precise flow control

- Excellent for fixed installations

- Available in nylon and polyurethane

- Best when: You need accurate tolerances, structure, or a straight run of controlled flow

Hose

- Flexible and often reinforced

- Can handle movement, vibration and repeated bending

- Typically used for portable tools, machinery and dynamic applications

- Best when: You need flexibility, high movement, or shock resistance

In short:

Use tube for precision, repeatability and fixed pipework.

Use hose for flexibility, mobility and absorbing movement.

Tubing Types and Their Applications

Below is a quick breakdown of each tubing type in this category along with the applications they’re best suited for.

Flexible Nylon Tube (Nylon 6)

A lightweight, durable tube ideal for high-pressure pneumatic systems.

Applications:

- Pneumatic control lines

- Instrumentation systems

- Air tools

- Automated machinery

- Environments where abrasion resistance and strength are essential

Why choose it:

Excellent pressure ratings and good UV stability.

Semi-Rigid Nylon Tube Food Grade (PA12)

A food-safe nylon tube suitable for direct contact with non-alcoholic consumables.

Applications:

- Food and beverage processing

- Dosing and filling equipment

- Pneumatic circuits requiring higher temperature resistance

- Fuel lines and lubrication systems

Why choose it:

Higher temperature capability plus chemical resistance to acids and alkalis.

Polyurethane Tube (PU)

Highly flexible tubing offering tight bend radii and impact resistance.

Applications:

- Compact pneumatic installations

- Robotics and automation

- Conveyance of air, liquids, gases, low-viscosity oils

- Where flexibility is more important than rigidity

Why choose it:

Soft, flexible, kink-resistant and ideal for confined spaces.

Flexi-Braid Polyurethane Braided Tube

Polyurethane tubing with an internal polyester braid for added pressure strength.

Applications:

- High-pressure air lines

- Industrial machinery

- Hydraulic return lines

- Environments involving vibration or movement

Why choose it:

Combines flexibility with increased burst resistance.

Polyurethane Anti-Spatter Tube

Twin-layer construction with a polyurethane core and a flame-retardant PVC jacket.

Applications:

- Robotic welding lines

- Automotive assembly

- Injection moulding cooling circuits

- Air and water transfer in harsh industrial settings

Why choose it:

Excellent abrasion resistance and protection from welding spatter and sparks.

Polyether Polyurethane Tube

Premium PU offering superior moisture resistance and flexibility.

Applications:

- Pneumatic control systems

- Conveying air, water, gases and compatible chemicals

- Tight-bend automated systems

- Environments with high humidity

Why choose it:

Outstanding resistance to hydrolysis, abrasion and bacterial growth.

Polyether Polyurethane Tube Colour Tinted

Same high-performance construction as above, but tinted for easy visual identification.

Applications:

- Pneumatic circuits requiring colour-coding

- Robotics and industrial automation

- Food processing lines

- Multi-line installations

Why choose it:

Clear visibility of media, quick line identification, and excellent flexibility.

Polyurethane Anti-Static Tube

PU tubing with conductive particles to dissipate electrostatic charge.

Applications:

- Electronics handling

- Semiconductor manufacturing

- Pneumatic systems in ATEX-sensitive environments

- Transfer of air and industrial fluids where static must be controlled

Why choose it:

Prevents static build-up, improves system safety and enhances operational reliability.

Nylon or Polyurethane - Which Should You Choose?

Choosing between nylon and polyurethane depends on the requirements of your system. Both materials are widely used in pneumatics, but they behave differently.

Nylon (PA6 / PA12)

- Higher working pressure capability

- Excellent abrasion and chemical resistance

- More rigid than polyurethane

- Better for long, straight runs

- Handles higher temperatures

- Choose nylon when: You need strength, pressure performance and durability in demanding industrial environments

Polyurethane (PU / Polyether PU)

- Far more flexible

- Very tight bend radii

- Better vibration absorption

- Softer feel and kink-resistance

- Ideal for compact assemblies and automation

- Choose polyurethane when: Your priority is flexibility, easy routing, quick installation or confined spaces

If you require any further information, our excellent customer service team is here to help so please call us on 01794 835835.