- Home

- Georg Fischer

- ABS Inch

- ABS Valves Inch

ABS Valves Inch

The Georg Fischer ABS Inch Valves range provides a high-quality, reliable solution for controlling fluid flow in ABS piping systems utilising imperial (“inch”) specifications. Engineered for robust performance, chemical compatibility, and regulatory compliance, these valves are suited for demanding applications across water treatment, food and beverage, HVAC, marine, chilled water and industrial settings.

Key Features & Technical Specifications

-

Valve Types Available:

-

Ball valves

-

Butterfly valve

-

Diaphragm valves

-

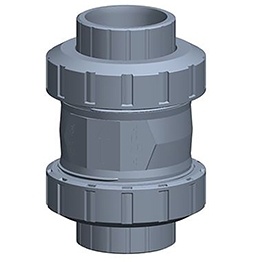

Check valves

-

Air Release Valves

-

-

Size & Pressure Range:

-

Inch sizes typically range from 3⁄8″ up to 12"

-

Working pressures up to 16 bar for many ABS inch valves, dependent on type, seal material, temperature, etc.

-

-

Temperature Range:

-

Valves operate from −40 °C to +60 °C under standard conditions.

-

-

Materials & Seals:

-

Bodies made from ABS (halogen-free), with a design focused on good mechanical strength and chemical resistance.

-

Seals are typically EPDM or FPM; sometimes PTFE seating, or combinations involving PTFE backing or inserts.

-

-

Jointing / Connection Types:

-

Solvent cement (socket), threaded, union joints depending on valve type.

-

Some valves include a double-union design for easier installation, maintenance, and disassembly.

-

-

Design & Safety Features:

-

Lockable handles (lever locks) to prevent unintentional operation.

-

Safety stem with a predetermined breaking point above the upper O-ring in double-union ball valves to prevent media leakage in the event of damage.

-

Integrated accessories: mounting inserts, electrical or pneumatic actuators, position feedback sensors, and manual spring return options.

-

-

Chemical & Environmental Performance:

-

High resistance to many chemicals, coolants (e.g. glycol mixtures), and good impact strength even at low temperatures.

-

Halogen-free material, which is beneficial in certain stringent environments (marine, food, etc.).

-

Why Choose Georg Fischer?

- Proven Reliability: GF is well-known for durability and consistency. Their valves are designed for long service life, even under challenging conditions (temperature fluctuations, chemical exposure).

- High Impact Strength & Low-Temperature Performance: ABS has superior resistance to impact even well below 0 °C; this reduces the risk of cracking or failure in cold climates.

- Full System Integrity: Using GF valves ensures compatibility with pipes and fittings in the ABS Imperial range—dimensional tolerances, material, jointing methods all match, minimising mismatches or installation issues.

- Safety Design Features: Things like lockable handles, safety stems, data matrix tracking, and union designs make maintenance safer and easier.

- Extensive Range & Customisation: GF offers a wide range of valve types, multiple sizes, various end connections, and options for automation (electric, pneumatic), actuation feedback, and more. This breadth allows matching precisely to application needs rather than compromise.

- Regulatory & Certification Confidence: Generic or cheaper valves may lack some of the international/UK approvals that GF holds. Specifying GF gives peace of mind that standards are met (WRAS, ISO, EN, BS, etc.).

- Support & Documentation: Full data sheets, CAD drawings, installation guides, technical advisory services—valuable for design, inspection, compliance, and ensuring installations are done right.

Georg Fischer Approvals

- BS standards (e.g. BS 5391-1)

-

What it is: British Standard for thermoplastic pipes, defining dimensions, tolerances, and performance characteristics.

-

Why it matters: Ensures compatibility with UK infrastructure and fittings; compliance with UK building and plumbing codes.

-

- EN / ISO standards

-

What it is: European and International standards for plastics, pipes, and fittings covering material properties, dimensions, and testing methods.

-

Why it matters: Provides global recognition of quality and performance; essential for engineering contracts and exports.

-

- WRAS (Water Regulations Approval Scheme)

-

What it is: UK approval confirming materials are safe for use with drinking water.

-

Why it matters: Essential for potable water systems; widely required for public and commercial projects.

-

- GOST-R

-

What it is: Russian/Eurasian certification demonstrating conformity with local standards.

-

Why it matters: Allows use in projects requiring compliance in Eastern Europe and Russia.

-

- Regulation 31 of the Water Supply (Water Quality) Regulations 2000

-

What it is: UK regulation ensuring materials in contact with drinking water are safe for human health.

-

Why it matters: Legally required for potable water installations; ensures systems pass inspection and approval.

-

- Internal GF testing

- What it is: Georg Fischer’s own stringent testing regime, including impact, tensile, and Charpy testing.

- Why it matters: Adds confidence in long-term durability, especially under stress and temperature variation.

If you require any further information, our excellent customer service team is here to help so please call us on 01794 835835.