Walraven Heavy Duty Expoxy Coated Unlined Pipe Clip

Technical Specification

-

Manufacturer: Walraven

-

Product Line: HD500 (Heavy Duty Unlined Clamps)

-

Materials:

- Body: Steel

- Coating: BIS UltraProtect 1000 (Approved under ISO 9227)

- Surface Protection: Black (RAL 9005) epoxy powder coating

-

Size Range:

- M8/M10: 12mm to 65mm

- M10/M12: 72mm to 116mm

-

Suitable for: Steel and stainless steel pipes, including fire mains (DIN 1988-600). Epoxy powder coating prevents contact corrosion between the clamp and the pipe.

-

Application Environment: Sensitive environments such as data centres, cleanrooms and hospitals.

-

Environmental Product Declaration: EPDs available for M8/M10 sizes.

-

Approvals: VdS, ITB (KOT)

-

Features:

-

Anti-loss washers

-

360° CO2-welded connection nut

- Coating prevents corrosion and zinc whiskers

-

Tested for fire safety

-

Captive locking nut

-

Wide opening

-

Description

Designed for high performance in demanding environments, this epoxy-coated heavy-duty clamp provides a secure fixing for steel and stainless steel pipework, including fire main installations. Its two-part construction and paired locking bolts create a rigid, reliable hold, while the anti-loss washers and captive locking nut design improve installation efficiency and safety.

The 360-degree CO2-welded connection nut offers exceptional strength for threaded rod attachment and support systems. A black epoxy powder coating (RAL 9005, 60 µm) provides enhanced corrosion resistance. It prevents contact corrosion when used with stainless steel pipe, ensuring long service life in both indoor and outdoor settings. As part of the BIS UltraProtect 1000 system, the clamp withstands a minimum of 1,000 hours of salt spray exposure, confirming durability in aggressive environments.

Benefits of Epoxy Coating:

- Zinc whiskers can pose a significant risk in data centres, cleanrooms, hospitals and other sensitive environments. These microscopic conductive filaments can detach from galvanised surfaces, potentially causing electrical short circuits, equipment failures and contamination issues.

- Because this clamp is epoxy-coated rather than zinc-plated, there is no exposed zinc surface from which whiskers can form. The fully encapsulated finish eliminates the risk of zinc whisker propagation, making it a safer choice for installations where equipment protection and air purity are critical.

-

Anti-loss washers are integrated components that prevent the clamp’s screws from detaching during installation. They secure the screw in place even when loosened, allowing the installer to position and adjust the clamp with one hand. This feature saves time, reduces the risk of dropped parts on site, and contributes to a safer and more efficient installation process.

Captive Nut and Screw

The nut and locking screw stay captive because of the plastic nut holder and anti-loss washer.

No Sharp Edges or Corners

The HD clamp is a straightforward assembly, well-finished with no sharp edges or corners.

Wide Opening

There is sufficient space between both clamp halves to place the pipe, meaning only one locking screw needs to be unscrewed.

Key Features & Benefits

- Heavy-duty design: Provides strong, reliable support for steel and stainless steel pipework

- 360-degree welded nut: Delivers a secure and robust threaded fixing point

- Fire mains compliant: Suitable for systems built to DIN 1988-600

- Corrosion-resistant coating: Black epoxy finish prevents contact corrosion, especially important with stainless steel pipe

- UltraProtect 1000 protection: Ensures excellent performance in indoor and outdoor environments

- High salt spray resistance: Proven durability with a minimum 1,000-hour ISO 9227 test rating

Approvals Explained

- ISO 9227:

- ISO 9227 is the global standard for salt spray testing, providing a controlled method to assess the corrosion resistance of metals and coatings under aggressive saline conditions.

- DIN 1988-600:

- DIN 1988-600 is a German standard that provides requirements for fire-fighting pipework within drinking water installations, ensuring safe separation and protection of the potable water system.

- VdS:

- VdS approval is a certification mark from VdS Schadenverhütung, an independent German testing and certification institution, for products and services in fire and security technology. This approval is only present sizes 25mm and above as per the HD500 Approval Sheet linked below.

- ITB (KOT):

- ITB (KOT) is a Polish National Technical Assessment issued by the Building Research Institute, confirming a construction product’s compliance and suitability for use when no harmonised EU standard applies.

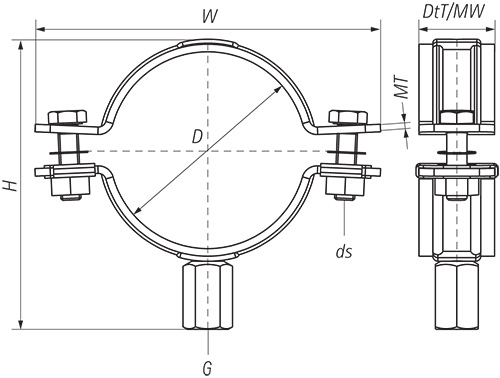

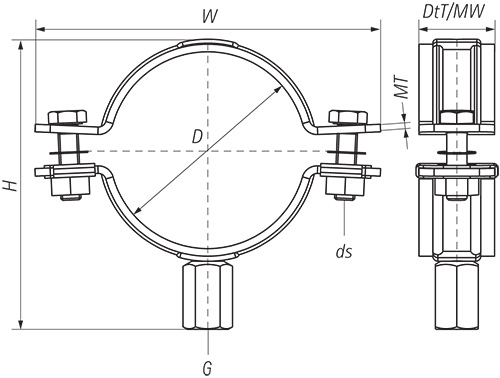

Dimensions

| Product Code | Manufacturer Code | Clamp Range (mm) | G (mm) | H (mm) | W (mm) | DtT (mm) | MW (mm) | MT (mm) | ds (Screw Size) | Max Load (N) |

| 492053 | 3303B016 | 12-16 | M8/M10 | 43 | 71.7 | 32.3 | 30 | 2.5 | M8 | 2100 |

| 492054 | 3303B023 | 19-23 | M8/M10 | 50 | 78.5 | 32.3 | 30 | 2.5 | M8 | 2100 |

| 492055 | 3303B026 | 22-26 | M8/M10 | 53 | 81.5 | 32.3 | 30 | 2.5 | M8 | 2100 |

| 492056 | 3303B030 | 25-30 | M8/M10 | 57 | 85 | 32.3 | 30 | 2.5 | M8 | 2100 |

| 492057 | 3303B036 | 31-36 | M8/M10 | 63 | 90.5 | 32.3 | 30 | 2.5 | M8 | 2100 |

| 492058 | 3303B042 | 37-42 | M8/M10 | 69 | 97.6 | 32.3 | 30 | 2.5 | M8 | 2100 |

| 492059 | 3303B052 | 47-52 | M8/M10 | 79 | 108.8 | 32.3 | 30 | 2.5 | M8 | 2100 |

| 492060 | 3303B058 | 53-58 | M8/M10 | 85 | 114 | 32.3 | 30 | 2.5 | M8 | 2100 |

| 492061 | 3303B065 | 59-65 | M8/M10 | 92 | 120.8 | 32.3 | 30 | 2.5 | M8 | 2100 |

| 492066 | 3304B078 | 72-78 | M10/M12 | 115 | 137 | 32.3 | 30 | 3 | M8 | 4000 |

| 492067 | 3304B092 | 86-92 | M10/M12 | 129 | 151 | 32.3 | 30 | 3 | M8 | 4000 |

| 492068 | 3304B116 | 108-116 | M10/M12 | 153 | 175 | 32.3 | 30 | 3 | M8 | 4000 |