Vulcathene Enfusion Single Socket Bend 135°

Technical Specification

- Manufacturer: Durapipe

- Material: Black co-polymer polypropylene (PP)

- Jointing method: Electrofusion using Enfusion Control Unit

- Bend angle: 135°

- Connection type: Enfusion socket x plain spigot

- Nominal sizes: 38mm to 152mm

- Operating temperature: -20°C to 100°C

- Standards: Manufactured to ISO 9001

- Approvals: BBA Approved, Certificate 24/7091

- Application: Chemical waste drainage systems

Description

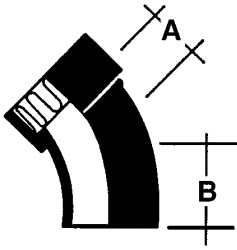

This Enfusion single socket bend is designed to introduce a 135° change of direction within Vulcathene chemical waste drainage systems where a fused joint is required on one side only. The fitting combines an Enfusion socket with a plain spigot end, making it well suited to installations where space, sequencing or connection method dictates a mixed jointing approach.

Fusion is carried out at the socket end using the Enfusion Control Unit, which activates the integral resistance wire moulded into the fitting. This controlled electrofusion process delivers consistent fusion temperature and time, producing a secure and repeatable joint at the most critical interface. The spigot end is designed to be fused into a compatible Enfusion socket elsewhere in the system.

Manufactured from black co-polymer polypropylene, the single socket bend offers excellent resistance to aggressive chemical waste and elevated operating temperatures. In applications where pipework is buried, routed overhead, installed within ceiling voids or incorporated into drainage stacks, Enfusion jointing provides a reliable alternative to mechanical connections.

Key Features & Benefits

- Single socket configuration: Allows a fused joint on one end with a plain spigot connection on the other

- 135° directional change: Provides a gradual change in direction within the drainage system

- Designed for chemical drainage: Suitable for laboratory, healthcare and industrial waste applications

- BBA approved: Independently certified for quality and long-term reliability

- Excellent chemical resistance: Polypropylene construction performs reliably in aggressive environments

- Ideal for complex installations: Useful where installation sequencing or access is restricted

| Product Code | Nom. Size (mm) | A (mm) | B (mm) | gms |

| 377016 | 38 | 19 | 38 | 80 |

| 377017 | 51 | 38 | 76 | 130 |

| 377018 | 76 | 51 | 95 | 260 |

| 377019 | 102 | 51 | 100 | 450 |

| 377020 | 152 | 43 | 114 | 1450 |