Durapipe HTA Serrated Stub Flanges

Technical Specification

- Manufacturer: Durapipe

- Material: Chlorinated polyvinyl chloride (CPVC)

- Application: Hot and cold water distribution

- Connection type: Solvent weld stub flange

- Design: Serrated face for improved flange stability

- Operating temperature range: 5°C to 90°C

- Maximum working pressure: Up to 25 bar

- Pressure rating at 70°C: 10 bar

- Suitability: Potable (drinking) water

- Fire classification: Euroclass B-s1,d0

- Approvals: WRAS approved

- System compatibility: HTA matched pipe, fittings and valves

Description

The HTA serrated stub flange is designed to create secure, demountable flanged connections within pressurised hot and cold water systems. Manufactured from high-performance CPVC, it provides excellent resistance to pressure, temperature variation and long-term mechanical stress.

The serrated face helps improve grip and alignment when assembled with backing rings and gaskets, reducing the risk of movement under load. Its smooth internal bore supports efficient flow, minimises frictional losses and helps prevent limescale build-up or biofilm formation, contributing to improved hygiene and system efficiency.

Produced as part of the HTA system by Aliaxis, this stub flange integrates seamlessly with compatible HTA pipes and valves. Lightweight construction and solvent weld installation allow for straightforward assembly without hot works, making it a reliable and cost-effective alternative to metal flanged connections.

Key Features & Benefits

- High pressure capability: Suitable for systems operating up to 25 bar

- Serrated flange face: Improves stability and alignment in flanged joints

- WRAS approved: Certified for potable water applications

- Smooth internal bore: Helps reduce friction, scale formation and biofilm risk

- Corrosion free construction: Will not rust, pit or degrade over time

- Wide temperature tolerance: Designed for use from 5°C to 90°C

- Fire performance: Achieves Euroclass B-s1,d0 classification

- HTA system matched: Engineered specifically for use with HTA pipes and fittings

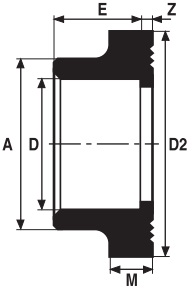

| Product Code | D (mm) | Z (mm) | E (mm) | D2 (mm) | M (mm) | A (mm) |

| 354327 | 25 | 3 | 20 | 41 | 7 | 33 |

| 354328 | 32 | 3 | 23 | 50 | 7 | 41 |

| 354329 | 40 | 3 | 27 | 61 | 8 | 50 |

| 354330 | 50 | 3 | 32 | 73 | 8 | 61 |

| 354331 | 63 | 3 | 39 | 90 | 9 | 76 |

| 354332 | 75 | 3 | 44 | 106 | 10 | 90 |

| 354333 | 90 | 5 | 51.5 | 125 | 11 | 108 |

| 354324 | 110 | 5 | 62 | 150 | 12 | 131 |

| 354325 | 125 | 5.5 | 67.5 | 170 | 13 | 147 |

| 354326 | 160 | 6 | 86 | 212 | 16 | 187 |

Working Pressures & Temperatures

| Temperature °C | (PN25) 70°C / 10 bar 60°C / 6 bar | (PN16) 70°C / 6 bar 60°C / 4 bar |

| Pressure (bar) | Pressure (bar) | |

| 5 | 25 | 16 |

| 20 | 25 | 16 |

| 40 | 20 | 12 |

| 60 | 13 | 8 |

| 70 | 10 | 6 |

| 80 | 6 | 4 |

| 90 | 4 | 2 |

Downloads