Walraven Bifix G2 Rubber Lined Clips

Technical Specification

- Manufacturer: Walraven

- Product Line: Bifix G2 Pipe Clamps

- Materials:

- Metal: Steel

- Coating: Walraven BIS UltraProtect 1000

- Lining: EPDM

- Size Range: 10mm to 225mm

- Temperature Rating: -30°C to +120°C

- Connection: Dual M8/M10 Thread

- Noise Reduction: Up to 23 dB(A) according to ISO 3822-1

- Suitable for: Uninsulated steel, copper, cast iron, & plastic multilayer pipe systems

- Application Environment: Suitable for use indoors and outdoors.

- Environmental Product Declaration: EPDs available.

- Approvals:

- ISO 9227

- DIN 4109

- ISO 3822-1

- RAL GZ 655

- ETA

Description

A premium quality pipe clamp offering a reliable two screw design with a quick closing mechanism that enables one-hand locking. The 2-component rubber lining supports easy pipe positioning during installation and provides a soft seating that helps minimise vibration and transmitted noise.

The durable steel construction is protected by the BIS UltraProtect 1000 system, giving strong corrosion resistance for both indoor and outdoor environments. Suitable for a wide variety of pipe materials and installation conditions, it performs effectively across a broad temperature range and is well-suited to HVAC, plumbing, and mechanical services where long-term reliability and acoustic control are important.

What is BIS UltraProtect 1000?

BIS UltraProtect 1000 (often abbreviated to BUP 1000) is a high-performance surface-treatment/coating system offered by Walraven for their pipe-clamps, rails, brackets and other fixing/support components.

- It is rated for use in corrosive environments classified as C1 to C4 under the standard ISO 12944‑2 (which covers atmospheric corrosion categories).

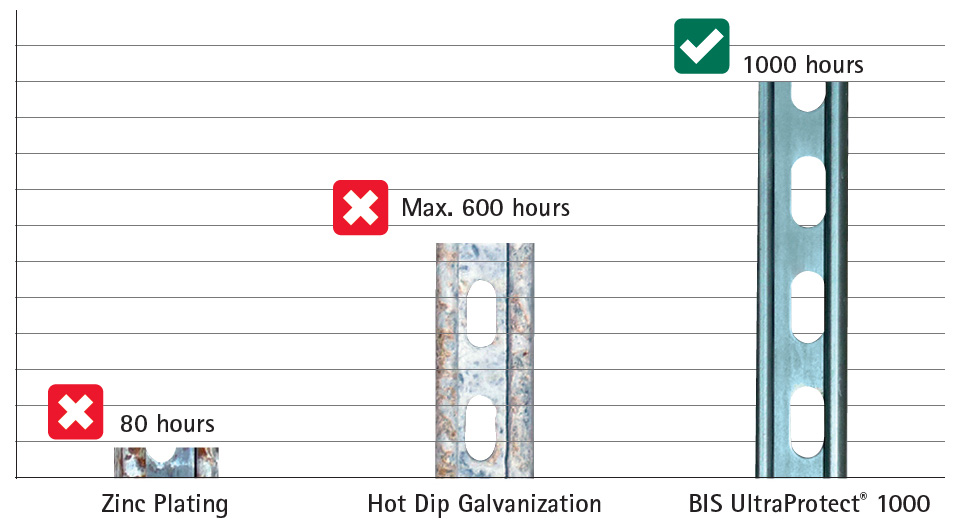

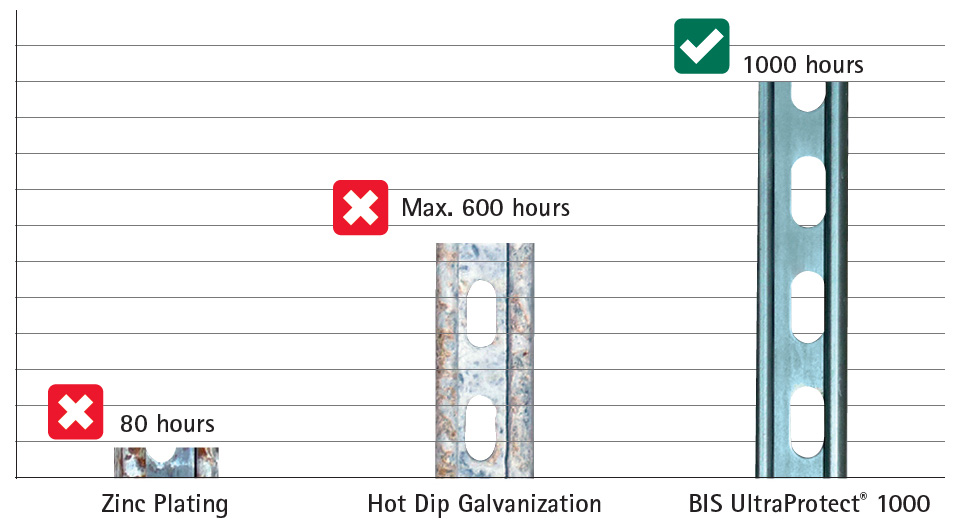

- The surface treatment achieves at least 1000 hours in a neutral salt spray (NSS) test per ISO 9227 with a maximum of 5% red rust (i.e., corrosion) on the test specimens.

- It is a robust alternative to hot‐dip galvanising (HDG). For comparison, typical HDG offers salt spray resistance in the region of 300–600 hours.

- The finish is smooth, visually attractive, and with a relatively thin protective layer, which offers advantages when you have threaded holes, rods, or complex geometry (where thick galvanising can cause build‐up or poor fits).

- Environmentally and production-wise, the treatment uses significantly fewer resources than HDG, including less energy, less water, and fewer emissions.

Key Features & Benefits

- Quick-closing mechanism: Enables the clamp to be locked with one hand, improving installation speed and ease of use.

- Two-screw clamp design: Provides secure and reliable pipe fixation with a robust connection.

- 2-component rubber lining: Facilitates simple and accurate pipe positioning during installation and supports quiet operation.

- Noise reduction up to 23 dB(A): The lining meets DIN 4109 and ISO 3822-1 requirements, helping reduce vibration and transmission of sound through piping systems.

- Steel construction with BIS UltraProtect® 1000 finish: Offers high corrosion resistance, suitable for indoor and outdoor use, enhancing lifespan in demanding environments.

- Wide temperature range (-30 °C to +120 °C): Versatile performance across diverse installation conditions, from chilled to heated systems.

- Certified for indoor/outdoor applications: Confidence in performance across many mechanical and plumbing infrastructure projects.

Approvals Explained

-

ISO 9227:

-

ISO 9227 is the global standard for salt spray testing, providing a controlled method to assess the corrosion resistance of metals and coatings under aggressive saline conditions.

-

-

DIN 4109:

-

DIN 4109 is Germany’s main building acoustics standard, defining how much noise is acceptable from plumbing, heating, and building systems, and how to test and limit it.

-

-

ISO 3822-1:

-

ISO 3822-1 is an international standard that sets out how to test the noise produced by sanitary and plumbing fittings and water-carrying components used in buildings.

-

-

RAL GZ 655:

-

RAL GZ 655 is a German quality assurance standard that guarantees pipe clamps and pipe fixing products meet high standards of strength, corrosion resistance, material consistency, and long-term safety.

-

-

ETA (European Technical Assesment):

-

A European Technical Assessment is a recognised, Europe-wide technical evaluation that allows a non-standard construction product to be CE-marked and marketed legally across the EU. It ensures consistent testing, reliable performance data, and compliance with the Construction Products Regulation.

-

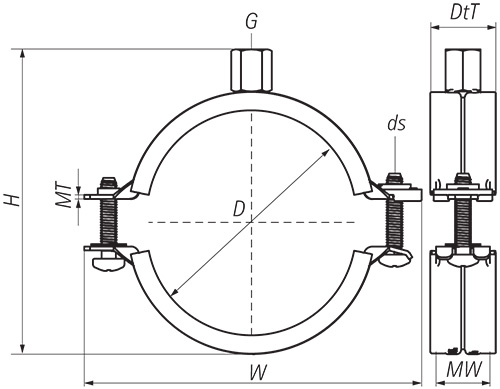

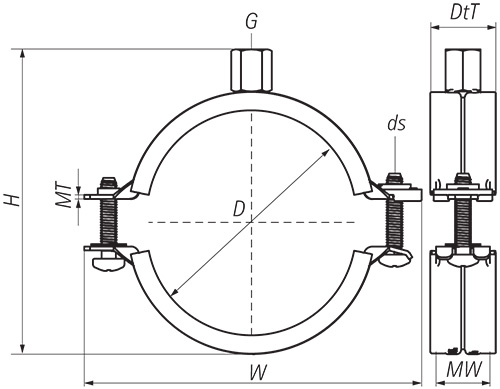

Dimensions

| Product Code | Manufacturer Code | Clamp Range (mm) | H (mm) | W (mm) | DtT (mm) | MW (mm) | MT (mm) | Screw Size / ds | Max Load (N) |

| 491891 | 31085014 | 10-14 | 43 | 59 | 24 | 20 | 1.25 | M6 | 700 |

| 491892 | 31085019 | 15-19 | 46 | 63 | 24 | 20 | 1.25 | M6 | 700 |

| 491893 | 31085023 | 20-23 | 50 | 68 | 24 | 20 | 1.25 | M6 | 700 |

| 491894 | 31085028 | 25-28 | 56 | 74 | 24 | 20 | 1.25 | M6 | 700 |

| 491895 | 31085035 | 31-35 | 62 | 80 | 24 | 20 | 1-25 | M6 | 700 |

| 491896 | 31085039 | 36-39 | 66 | 84 | 24 | 20 | 1.25 | M6 | 700 |

| 491897 | 31085045 | 40-45 | 73 | 91 | 24 | 20 | 1.25 | M6 | 700 |

| 491898 | 31085052 | 48-52 | 79 | 97 | 24 | 20 | 125 | M6 | 700 |

| 491899 | 31085058 | 54-58 | 86 | 104 | 24 | 20 | 1.25 | M6 | 700 |

| 491900 | 31085064 | 60-64 | 91 | 109 | 24 | 20 | 1.25 | M6 | 700 |

| 491901 | 31085070 | 66-70 | 100 | 118 | 25 | 20 | 1.5 | M6 | 800 |

| 491902 | 31085079 | 75-79 | 107 | 125 | 25 | 20 | 1.5 | M6 | 800 |

| 491903 | 31085083 | 80-83 | 114 | 132 | 25 | 20 | 1.5 | M6 | 800 |

| 491904 | 31085091 | 88-91 | 123 | 142 | 29 | 23 | 2 | M6 | 1700 |

| 491905 | 31085097 | 92-97 | 132 | 147 | 29 | 23 | 2 | M6 | 1700 |

| 491906 | 31085105 | 100-105 | 137 | 155 | 29 | 23 | 2 | M6 | 1700 |

| 491907 | 31085115 | 108-115 | 145 | 164 | 29 | 23 | 2 | M6 | 1700 |

| 491908 | 31085130 | 125-130 | 162 | 181 | 29 | 23 | 2 | M6 | 1700 |

| 491909 | 31085140 | 133-140 | 171 | 189 | 29 | 23 | 2 | M6 | 1700 |

| 491910 | 31085160 | 152-160 | 187 | 209 | 29 | 23 | 2 | M6 | 1700 |

| 491911 | 31085169 | 165-169 | 203 | 225 | 31 | 25 | 2.5 | M8 | 2000 |

| 491912 | 31085180 | 176-180 | 209 | 238 | 31 | 25 | 2.5 | M8 | 2500 |

| 491913 | 31085200 | 192-200 | 238 | 257 | 31 | 25 | 2.5 | M8 | 2500 |

| 491914 | 31085210 | 205-210 | 249 | 269 | 31 | 25 | 2.5 | M8 | 2500 |

| 491915 | 31085225 | 219-225 | 265 | 283 | 31 | 25 | 2.5 | M8 | 2500 |