MDPE Barrier Pipe: Made Simple

Turning contaminated sites into safe supplies: everything you need to know about MDPE Barrier Pipe

Published: 26th September 2025 - Updated: 14th November 2025

In this guide, you'll learn everything you need to know about MDPE Barrier Pipe, from the basics of what it's made from, all the way through to installation.

We hope this guide can answer your questions, but should you need further advice, please get in contact with us.

What is MDPE Barrier Pipe?

MDPE barrier pipe is a type of plastic pipe specifically designed to stop contaminants from getting into the water supply. A standard plastic pipe (like MDPE) can allow contaminants to permeate through over time. A barrier pipe prevents this by having an additional protective layer, usually aluminium, that acts as a shield.

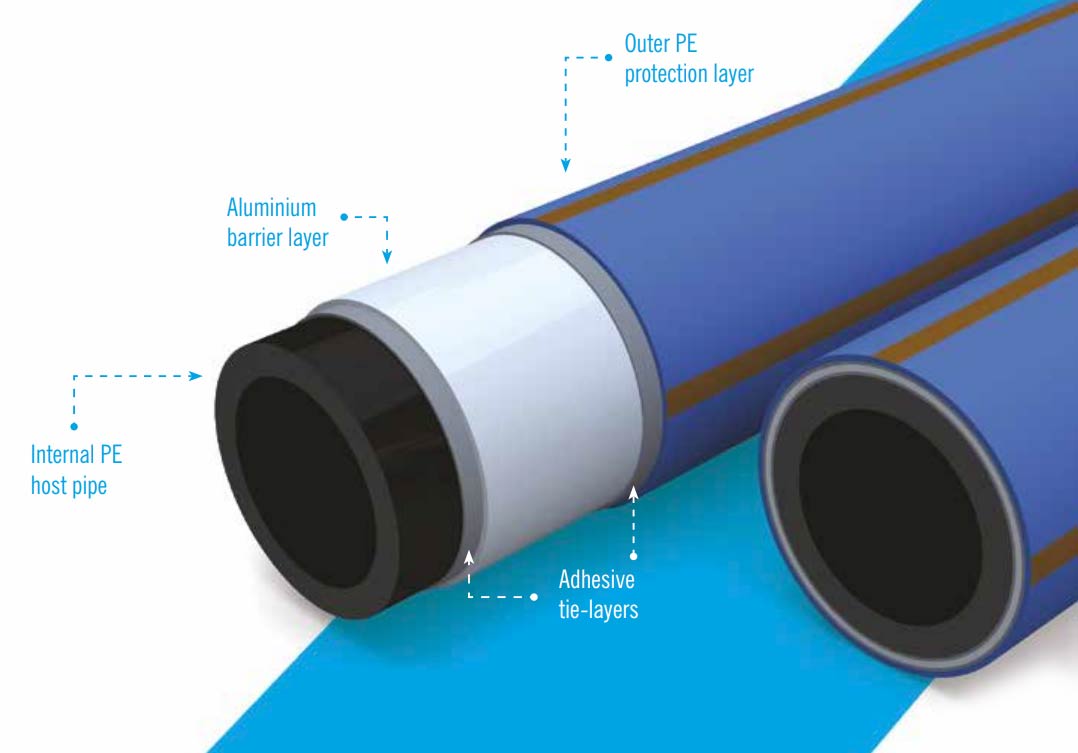

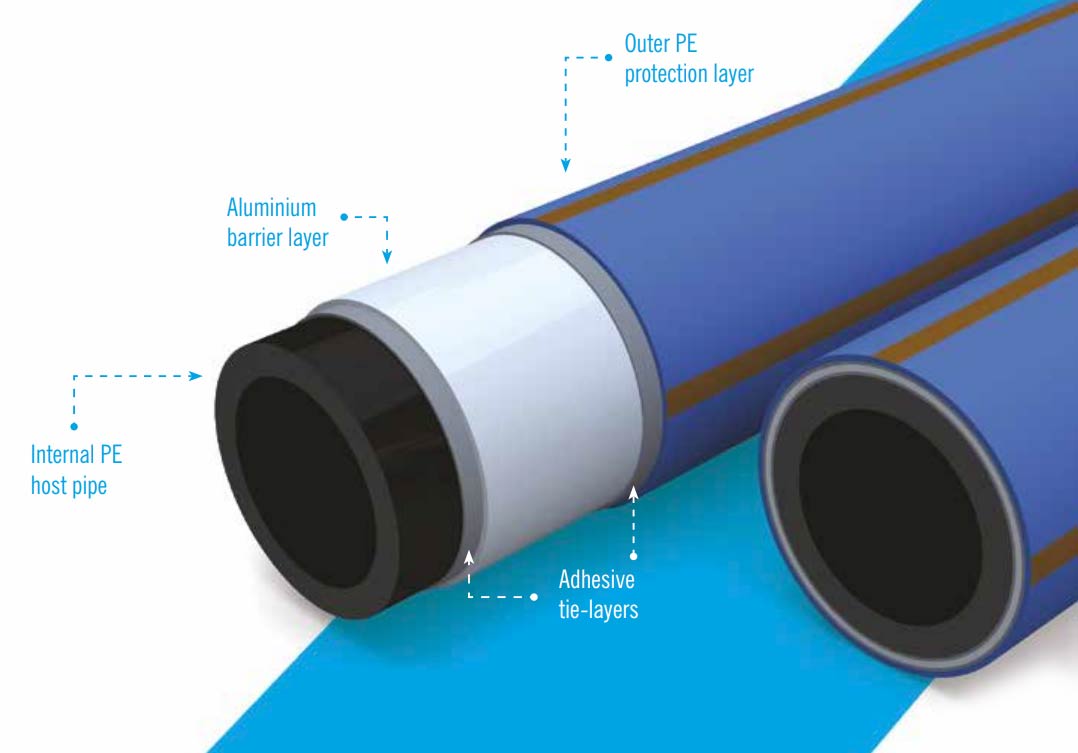

What is MDPE Barrier Pipe made from?

Barrier pipe is based on MDPE, but with added protective layers that form a barrier against contaminants. The exact make-up varies slightly by brand, but most share a similar multi-layer structure:

- Inner Core: Standard MDPE, which provides strength, flexibility, and water safety.

- Barrier Layer: Often a thin layer of aluminium. This layer prevents hydrocarbons and other pollutants in the soil from migrating through the pipe wall.

- Outer Layer: Another layer of MDPE or protective plastic, which shields the barrier and adds durability against impact and abrasion.

- Adhesive Layers: In some systems, bonding agents are used between layers to keep the structure intact.

The diagram shown below is a disassembled example of Aliaxis' Protecta-Line pipe.

Is MDPE Barrier Pipe known by any other names?

MDPE barrier pipe is the generic name for this type of product, although some manufacturers brand theirs differently, for example, Aliaxis markets its version under the name Protecta-Line. You might also hear it referred to as multi-layer pipe, contaminated land pipe, brownfield pipe, or barrier pipe. Please note, however, that barrier pipe can also refer to other products like PEX or PB pipe, which are generally used for domestic plumbing.

What is MDPE Barrier Pipe used for?

MDPE barrier pipe is primarily used to supply clean, safe drinking water in areas where the surrounding ground may be contaminated. Standard MDPE pipe is suitable for most applications, but in brownfield sites or land with a history of industrial use, there is a risk that substances like fuel, solvents, or other chemicals could leach through the pipe wall. The barrier layer in the MDPE barrier pipe prevents this, ensuring the water supply remains uncontaminated and fit for human consumption. It is commonly specified for new housing developments, especially those built on reclaimed or previously developed land.

What is a Brownfield Site?

A brownfield site is an area of land previously developed that is now disused or derelict. Often, these sites were previously used for industrial and commercial purposes as well as for landfill. Brownfield sites have a risk of contamination from past use, such as chemicals and fuels from machinery and industrial vehicles. Some sites will require additional clean-up to be built on, but there is no way of ensuring all potential contaminants have been removed from the soil. Redeveloping these sites is generally encouraged in the UK, and it helps reduce the pressure of building on greenfield sites (undeveloped countryside). Commonly, these brownfield sites are used to build housing, commercial buildings or infrastructure projects, which is why it is important to use barrier pipe on these sites, as it prevents the previously mentioned contaminants from entering the safe drinking water supply through permeation, which could happen if regular MDPE or other plastic pipes are used.

What approvals does MDPE Barrier Pipe have?

The MDPE barrier pipe we supply is Protecta-Line, manufactured by Aliaxis. It is the golden standard for UK water safety, holding many approvals and often specified for a project due to its known reputation. Protecta-Line conforms to the following approvals;

Regulations 31 and 33 of the DWI (Drinking Water Inspectorate):

- What is it?

- Regulation 31 of The Water Supply (Water Quality) Regulations 2016 implements Article 10 of the Council of the European Union Drinking Water Directive (DWD) in England and Wales for all chemicals and construction products used by water undertakers, from the source of the water, up to the point of delivery to the consumer’s building. It sets out how approvals can be given to such construction products and materials that do not prejudice water quality and consumer safety. Regulation 33 is the Scottish equivalent.

- What does it mean?

- A DWI-approved barrier pipe, such as Protecta-Line, is certified by the DWI under Regulation 31 to ensure the safe transport of drinking water, even through contaminated ground. By selecting a Regulation 31-compliant system, you can be confident that your project meets strict water quality standards, minimises contamination risks, and delivers a dependable supply of safe, clean water to communities.

- Does it need to be renewed?

- Yes, products covered by Regulation 31 are regularly reviewed to confirm they continue to meet current standards. Protecta-Line's certification has recently been renewed through to 31 October 2029, reflecting its ongoing commitment to upholding vital safety and quality standards.

WRAS:

- What is it?

- WRAS approval (Water Regulations Advisory Scheme approval) is a certification that shows a plumbing product or material complies with the UK’s Water Supply Regulations. WRAS approval is widely recognised by water authorities, specifiers, and contractors, giving reassurance that a product is compliant and suitable for use in the UK water supply network.

- What does it mean?

- When a product is WRAS Approved, it has been independently tested for things such as:

- Safety for drinking water: It won’t leach harmful substances or taint the taste/odour.

- Regulatory compliance: It meets all the legal requirements for installation in the UK.

- When a product is WRAS Approved, it has been independently tested for things such as:

BS 8588:

- What is it?

- BS 8588 is a British standard that serves technical specifications for polyethylene pressure pipes for potable water supply in contaminated land, ensuring water purity and consistency in the potable water supply applications. It specifies requirements for the materials, mechanical performance, dimensions, and effect on water quality of polyethylene pipes with an aluminium barrier layer and associated fittings/joints for potable water supply installed in contaminated ground.

- What does it mean?

- Polyethylene pressure pipes are widely used for applications such as potable water supply, natural gas distribution, lawn irrigation, sewers, drainage, and even waste systems. Their key qualities, toughness, light weight, and flexibility, make them a reliable and long-lasting choice, particularly for carrying drinking water.

- Adopting BS 8588 ensures that polyethylene pressure pipes are designed and assessed to meet stringent requirements, including resistance to chemicals, giving confidence in their performance for critical water distribution applications.

BS EN12201-2:

- What is it?

- BS EN12201-2 specifies the characteristics of pipes made from polyethylene for both buried and above-ground use, intended for transporting water for human consumption, raw water prior to treatment, drains and sewers under pressure, vacuum sewer systems and water for any other purpose except industrial applications. It dictates certain properties of the pipes, such as dimensions, testing, marking and how they should be manufactured.

- What does it mean?

- This standard ensures the quality and safety of polyethylene pipe systems that are used for water and wastewater management.

How is MDPE Barrier Pipe measured?

MDPE barrier pipe is sold based on the external diameter of the core pipe; the product then has the layer of protection and the outer coating added, meaning the end product is slightly larger. For example, a 63mm length of Protecta-Line actually measures approximately 65mm outer diameter. This can be hard to understand, but we've listed all the details below for you!

Click on the expanding table below for specific details on Protecta-Line Pipe!

| Pipe Size (mm)* | SDR | Min OD (mm) | Max OD (mm) | Average Bore (mm) | Min Wall Thickness (mm) | Max Wall Thickness (mm) | Pressure Rating (Bar) | Average Weight (kg/m) |

|---|---|---|---|---|---|---|---|---|

| 25 | 11 | 26.2 | 27.4 | 20.0 | 3.0 | 3.7 | 12.5 | 0.3 |

| 32 | 11 | 33.3 | 34.5 | 26.0 | 3.7 | 4.4 | 12.5 | 0.4 |

| 63 | 11 | 64.3 | 65.6 | 50.9 | 6.5 | 7.6 | 12.5 | 1.3 |

| 90 | 11 | 92.2 | 93.5 | 72.9 | 9.3 | 10.7 | 16 | 2.6 |

| 110 | 11 | 112.2 | 113.5 | 89.2 | 11.1 | 12.7 | 16 | 3.7 |

| 125 | 17 | 127.2 | 128.5 | 109.6 | 8.5 | 9.8 | 10 | 3.4 |

| 160 | 17 | 163.2 | 165.1 | 141.1 | 10.7 | 12.4 | 10 | 5.4 |

| 180 | 17 | 183.3 | 185.4 | 158.8 | 11.9 | 13.7 | 10 | 6.8 |

All measurements are averages in accordance with BS 8588 TYPE A. * The size is the nominal core pipe outside diameter.

Does MDPE Barrier Pipe freeze?

Barrier pipe is just as vulnerable to freezing as standard MDPE pipe; the barrier layer doesn’t provide frost protection. Like all plastic water pipes, if the water inside falls below 0°C, it can expand and cause damage. However, MDPE and barrier MDPE are more resistant to freezing than rigid materials such as copper, thanks to their flexibility, which allows them to expand slightly without immediately bursting. To reduce the risk of freezing, pipes should be installed at a minimum depth of 900mm below ground level, or insulated if exposed outdoors. It’s also sensible to avoid dead legs, where standing water can freeze more easily.

How long does MDPE Barrier Pipe last?

It’s challenging to provide an exact figure, as lifespan depends on several factors; however, an MDPE barrier pipe is expected to last at least 50 years, the same as a normal MDPE. In fact, recent studies suggest it could even exceed 100 years in service!

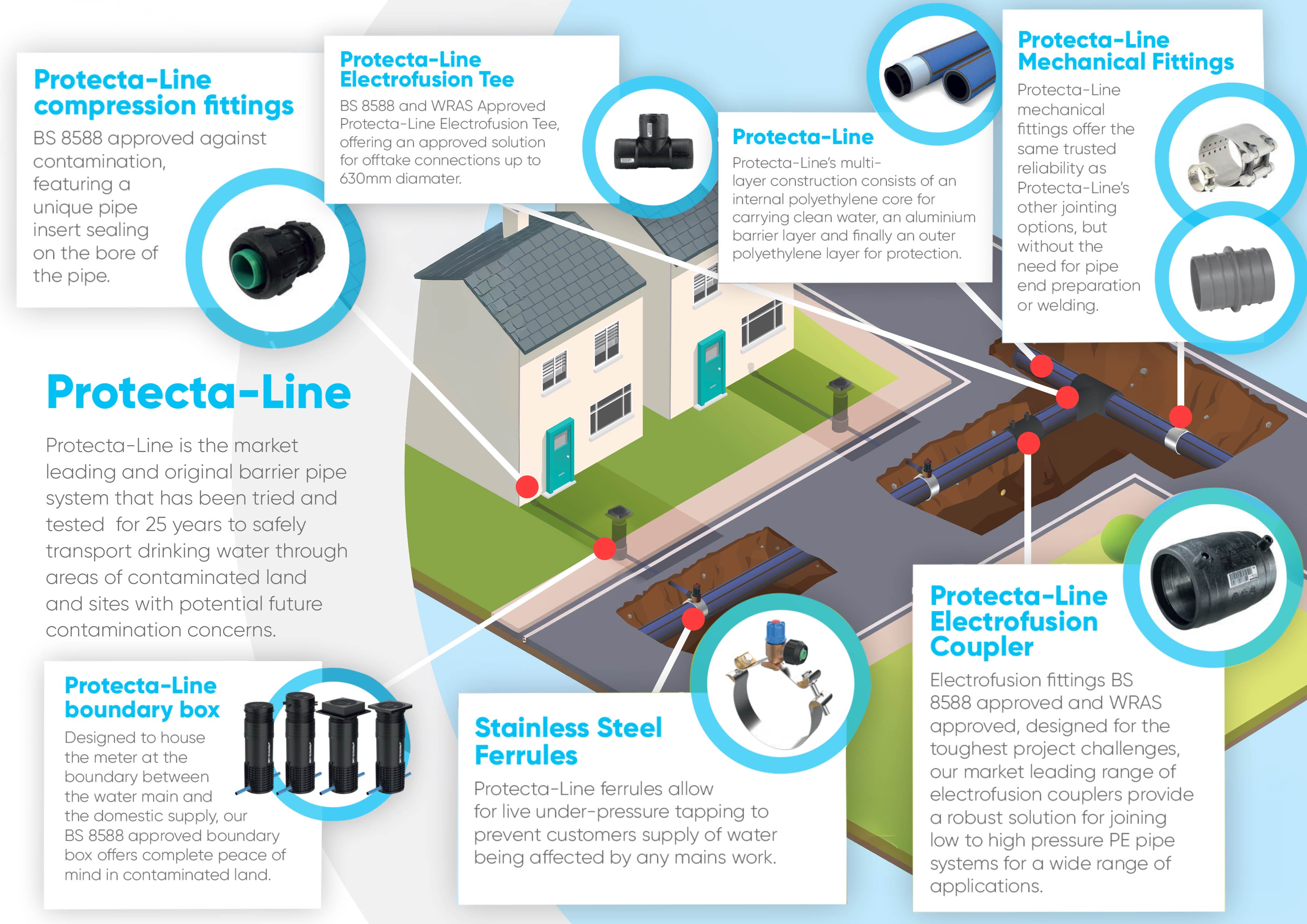

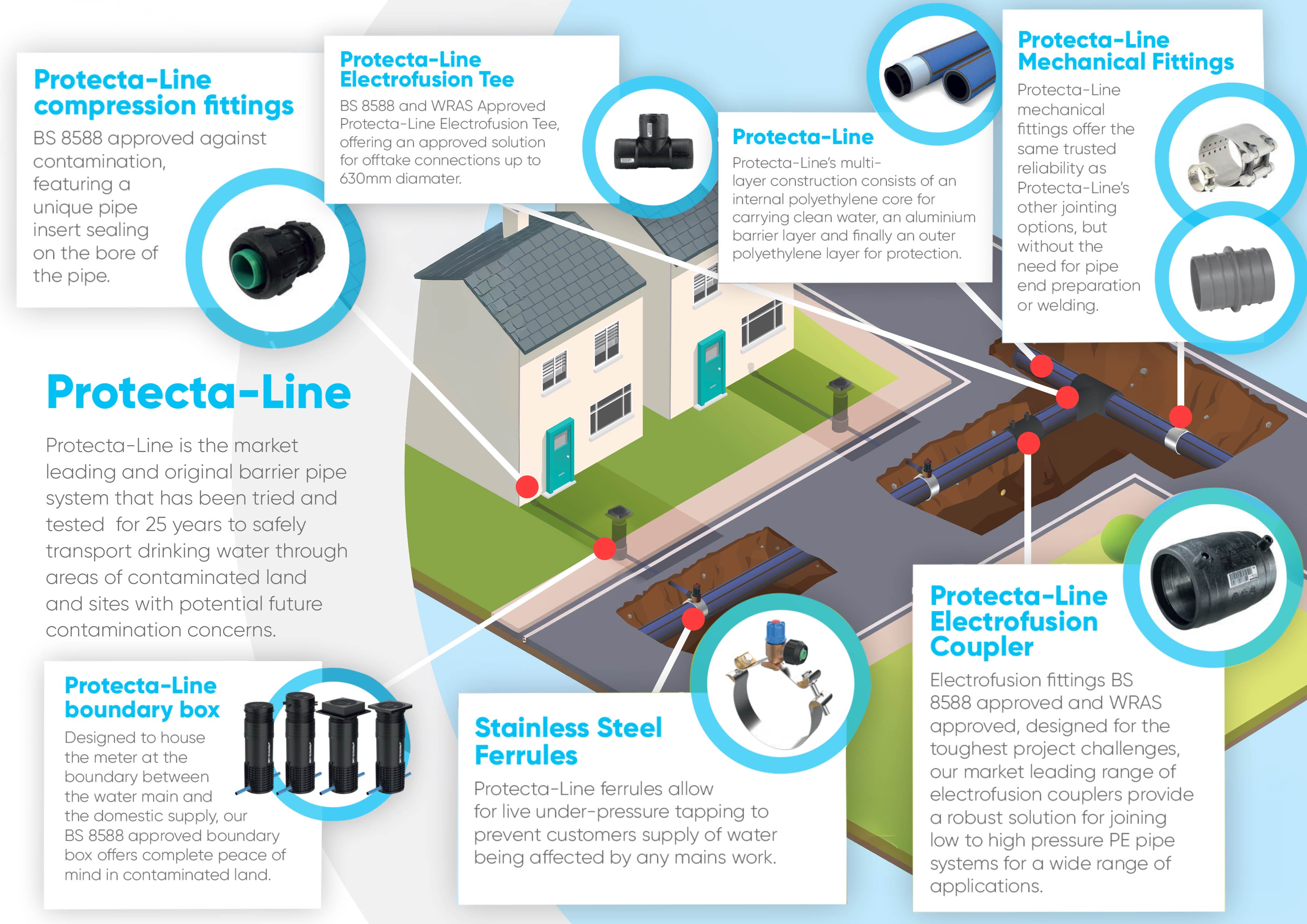

What fittings can be used on MDPE Barrier Pipe?

For small-bore MDPE barrier pipe, the most common choice is compression fittings, as they are cost-effective, simple to install, and don’t require specialist tools. Another option is electrofusion, which becomes the preferred method for larger diameters, typically 90 mm and above.

When using compression fittings, we recommend a strap wrench to ensure they are tightened correctly. Unlike standard MDPE, separate pipe liners are not needed when working with MDPE barrier pipe, as they are included as a part of the fitting.

How do I cut MDPE Barrier Pipe?

For the easiest and cleanest results, we recommend using a ratchet cutter. Start by pulling back the button on top to retract the blade, then position the pipe against the grooved base. Squeeze the handle repeatedly until the cut is finished. Be sure to keep the cutter straight as you work; this helps protect the aluminium inner layer from damage.

For a full demonstration of this method, along with other tips, watch our video below!

How do I join MDPE Barrier Pipe together?

The most popular method for joining MDPE barrier pipe (as mentioned above) is by the use of compression fittings. These are incredibly easy to install, the most cost-effective and do not require the use of any specialist equipment.

Important note: You must use Barrier Pipe specific fittings as these account for the extra layers on the pipe; standard MDPE fittings will not fit over the pipe.

Compression Fittings

- Disassemble the fitting, remove the nut and white split ring and slide both onto the pipe, ensuring the taper of the split ring faces toward the nut

- Insert the pipe insert, push it into the end of the pipe, then gently tap with a rubber mallet or similar tool. Ensure the seal ring is seated correctly on the insert, as it could move out of place during this process

- Position the split ring and nut, slide the split ring firmly up against the insert and push the nut up behind it; these parts should click into place

- Assemble the joint. Thread the body of the fitting back into the nut until the thread is no longer visible

Electrofusion Fittings

The other method is by Electrofusion. Electrofusion is a method of joining plastic pipes by using fittings with built-in electric heating elements, which are used to weld the joint together. Electrofusion fittings can be used for MDPE barrier pipe; however, you must use the barrier-specific fittings.

For a detailed guide, check out the videos below, created by the manufacturer themselves!

90-180mm

180mm+

Butt Fusion

For the largest sizes of MDPE barrier pipe, it becomes impractical to use any form of coupler due to the size. At these sizes, a special machine is used; sometimes it is mounted on tracks due to the weight of the pipe. In some configurations, it can even feature a circular saw to cut the pipe to length.

The first part of the process utilises the pipe preparation module, which simultaneously shaves both pipes' connecting faces, ensuring a uniform and tight fit. This element is then removed, and the pipe should be inspected to make sure there are no visible gaps between the two surfaces when pushed together. Once this process is complete, the heating element is mounted to the machine, which heats both ends of the pipes and then automatically pushes both ends into each other, forming a butt fusion weld. Once cooled, the bead created should be removed, inspected and tested. If it were to come apart or snap, then the joint should be cut out and redone.

How do I connect MDPE Barrier Pipe to a residential or commercial building?

Connecting your barrier pipe to a house or commercial building is the last step to providing safe water to a family or business; however, it is very important to install it correctly. Otherwise, it could compromise the protected water from the main barrier pipeline. A few different products are used to ensure this is done correctly. We'll go through each one for you here!

Ferrule Off Take:

- The first step involves choosing the correct ferrule off-take. While several types are available, the most commonly used is the right-angle self-tapping off-take. This design makes it easy to mount directly on top of the pipe, allowing a smaller pipe to branch off neatly towards the building.

Size Down Pipe:

- The off-take provides a smaller size of barrier fitting, usually 25 or 32mm, which can then be run into the building. This provides enough water for the residence while also downsizing the pipe, reducing cost and workload.

Barrier Boundary Box:

- These function in the same way as standard boundary boxes but are fitted with barrier pipe connections and tails, ensuring the same level of protection as the rest of the pipe system. They are designed to house water meters and include a stopcock, allowing the water supply to be shut off at street level when required.

- Aliaxis' Protecta-Line Boundary Boxes offer a wide variety of lid types, making them suitable for many different brownfield site locations.

Final Connection:

- Once inside the building, the pipework can be safely transitioned back to regular MDPE or any other pipe that may be used to convey the water. There are a few ways of doing this, but commonly, you may use a female adaptor attached to a manifold and then run regular MDPE, copper or PEX/PB pipe from that to the different outlets around the building. An alternative way is to use a Barrier Pipe x MDPE coupling; these are ideal if the water line needs to run further inside the building before being split up.

We hope this guide has not only answered your questions but also highlighted the vital role of using the right level of protection on brownfield sites. By doing so, we can ensure that communities across the UK continue to enjoy reliable access to clean, safe drinking water. Thank you for reading!

Still have questions? Get in touch via the contact us page.