Pipe

Technical Specification

- Material: Chlorinated polyvinyl chloride (CPVC)

- Manufacturer: Durapipe

- Operating temperature range: 5°C to 95°C

- Maximum working pressure: Up to 16 bar

- Length supplied: 5 metres

- Jointing method: Solvent welding using PVC-C solvent cement and cleaner

- Approvals: WRc tested, WRAS approved

- Manufacturing standard: BS EN ISO 9001 quality system

- Suitability: Potable water and aggressive industrial fluids

Description

This high-performance CPVC pipe is engineered for the safe and reliable transportation of hot, corrosive and aggressive fluids where traditional materials such as metal or standard plastics may fail. Designed for demanding industrial and process applications, it performs consistently at elevated temperatures while maintaining excellent pressure capability.

Manufactured using Corzan CPVC compounds, the pipe offers outstanding resistance to acids, alkalis, effluents and demineralised water. Its non-toxic, taint-free formulation makes it suitable for potable water and sensitive applications, including food, beverage and medical processes, subject to site testing.

The smooth internal bore reduces friction losses and inhibits scale build-up, improving flow efficiency and lowering long-term pumping costs. Lightweight construction simplifies handling and installation, while solvent-weld jointing provides fast, reliable assembly without the need for hot works permits.

This pipe forms part of a fully matched Corzan CPVC system and is joined to compatible fittings using PVC-C solvent cement, available within the Corzan accessories range.

Key Features & Benefits

- Excellent chemical resistance: Suitable for acids, alkalis, effluents and aggressive industrial fluids

- High temperature performance: Operates reliably at temperatures up to 95°C

- Pressure rated: Up to 16 bar for demanding process conditions

- WRAS approved: Suitable for potable water with no risk of taint or contamination

- No hot works required: Solvent welding removes the need for welding permits

- Lightweight construction: Easier handling than steel or copper, reducing installation time

- Smooth bore design: Lower pressure drop, reduced scale formation and improved energy efficiency

- Abrasion resistant: Performs well against slurries that can damage metal systems

- Sustainable material balance: Lower petroleum content compared to many plastics

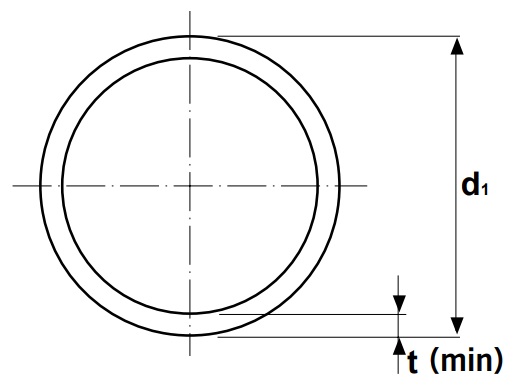

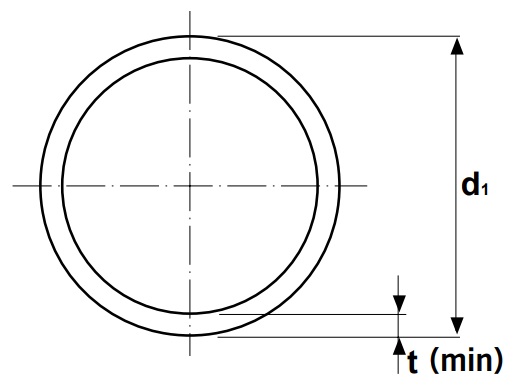

| SKU | Size d1 (mm) | t (mm) | Standard Length (m) | kg/m |

| 351181 | 16 | 1.2 | 5 | 0.11 |

| 351182 | 20 | 1.5 | 5 | 0.17 |

| 351183 | 25 | 1.9 | 5 | 0.26 |

| 351184 | 32 | 2.4 | 5 | 0.42 |

| 351185 | 40 | 3 | 5 | 0.63 |

| 351186 | 50 | 3.7 | 5 | 0.97 |

| 351187 | 63 | 4.7 | 5 | 1.53 |

| 351188 | 75 | 5.6 | 5 | 2.2 |

| 351189 | 90 | 6.7 | 5 | 2.88 |

| 351190 | 110 | 8.2 | 5 | 4.31 |

| 351191 | 160 | 7.7 | 5 | 6.06 |