Walraven Heavy Duty Rubber Lined Pipe Clip

Technical Specification

-

Manufacturer: Walraven

-

Product Line: HD1501 (Heavy Duty Rubber Lined Clamps)

-

Materials:

- Metal: Steel

- Coating: BIS UltraProtect 1000 (Approved under ISO 9227)

- Lining: Sound-insulating EPDM rubber lining (In accordance with DIN 4109)

-

Size Range:

- M8/M10: 15mm to 68mm

- M10/M12: 65mm to 227mm

- M16: 159mm to 509mm

-

Noise Reduction: Up to 18 dB(A) (In accordance with ISO 3822-1)

-

Suitable for: Uninsulated metal pipe systems

-

Application Environment: Suitable for use indoors and outdoors.

-

Environmental Product Declaration: EPDs available.

-

Approvals: ETA, ISO 3822-1, RAL-GZ 655/B, RAL-GZ 656.

-

Features:

-

Anti-loss washers

-

CO2-welded connection nut

-

Tested for fire safety

-

Captive locking nut

-

Wide opening

-

Description

A robust, heavy-duty pipe support designed for securely fixing metal pipework in demanding environments. The two-part body and paired locking bolts create a reliable, rigid fastening, while the anti-loss washers ensure ease of installation even in overhead or restricted locations. The CO2-welded connection nut increases structural integrity, providing a secure mounting point for threaded rod or brackets.

The BIS UltraProtect 1000 finish delivers exceptional corrosion resistance for both indoor and outdoor applications, making it suitable for building services, industrial systems, plant rooms, and infrastructure projects. The integrated rubber lining reduces vibration and operational noise, supporting compliance with acoustic standards and improving overall system comfort and performance.

-

Anti-loss washers are integrated components that prevent the clamp’s screws from detaching during installation. They secure the screw in place even when loosened, allowing the installer to position and adjust the clamp with one hand. This feature saves time, reduces the risk of dropped parts on site, and contributes to a safer and more efficient installation process.

Captive Nut and Screw

The nut and locking screw stay captive because of the plastic nut holder and anti-loss washer.

No Sharp Edges or Corners

The HD clamp is a straightforward assembly, well-finished with no sharp edges or corners.

Wide Opening

There is sufficient space between both clamp halves to place the pipe, meaning only one locking screw needs to be unscrewed.

Key Features & Benefits

- Heavy-duty construction: Provides a secure and durable fixing for metal pipework in demanding installations

- Two locking bolts: Ensure a firm clamping force and stable alignment

- CO2 welded connection nut: Offers a strong and reliable threaded fixing point

- UltraProtect 1000 coating: Delivers long-term corrosion resistance for indoor and outdoor environments

- High salt spray performance: Withstands 1,000 hours of testing to ISO 9227 with minimal red rust

- Acoustic rubber lining: Reduces vibration and noise transmission, supporting compliant, quieter pipe systems

- Fire tested: Suitable for applications requiring proven fire performance

Approvals Explained

-

ETA (European Technical Assessment):

- A European Technical Assessment is a recognised, Europe-wide technical evaluation that allows a non-standard construction product to be CE-marked and marketed legally across the EU. It ensures consistent testing, reliable performance data, and compliance with the Construction Products Regulation.

-

ISO 3822-1:

- ISO 3822-1 is an international standard that sets out how to test the noise produced by sanitary and plumbing fittings and water-carrying components used in buildings.

-

RAL-GZ 655/B:

- RAL-GZ 655/B is a recognised German quality standard that certifies the safety, strength and reliability of pipe clamps and support systems through strict, independently verified testing.

-

RAL GZ-656:

- RAL‑GZ 656 is a German quality standard for fire-tested pipe supports. It certifies that pipe clamps, brackets, rails and related supports have been subjected to independent fire-resistance testing.

-

DIN 4109:

- DIN 4109 is Germany’s main building acoustics standard, defining how much noise is acceptable from plumbing, heating, and building systems, and how to test and limit it.

-

ISO 9227:

-

ISO 9227 is the global standard for salt spray testing, providing a controlled method to assess the corrosion resistance of metals and coatings under aggressive saline conditions.

-

For a full list of approvals for each specific item, please see the datasheet linked below.

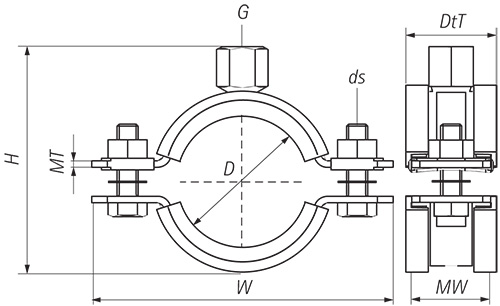

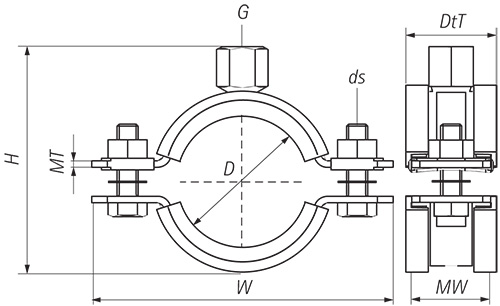

Dimensions

| Product Code | Manufacturer Code | Clamp Range (mm) | G (mm) | H (mm) | W (mm) | DtT (mm) | MW (mm) | MT (mm) | ds (Screw Size) | Max Load (N) |

| 491976 | 33138019 | 15-19 | M8/M10 | 55 | 81 | 30 | 30 | 2.5 | M8 | 1500 |

| 491977 | 33138023 | 19-23 | M8/M10 | 58 | 84 | 30 | 30 | 2.5 | M8 | 1500 |

| 491978 | 33138029 | 25-29 | M8/M10 | 64 | 91 | 30 | 30 | 2.5 | M8 | 1500 |

| 491979 | 33138035 | 30-35 | M8/M10 | 70 | 98 | 30 | 30 | 2.5 | M8 | 1500 |

| 491980 | 33138045 | 40-45 | M8/M10 | 80 | 109 | 30 | 30 | 2.5 | M8 | 1500 |

| 491981 | 33138051 | 46-51 | M8/M10 | 86 | 115 | 30 | 30 | 2.5 | M8 | 1500 |

| 491982 | 33138059 | 53-59 | M8/M10 | 93 | 122 | 30 | 30 | 2.5 | M8 | 1500 |

| 491983 | 33138064 | 59-64 | M8/M10 | 99 | 129 | 30 | 30 | 2.5 | M8 | 1500 |

| 491984 | 33148071 | 65-71 | M10/M12 | 116 | 136 | 30 | 30 | 3 | M8 | 2300 |

| 491985 | 33148078 | 72-78 | M10/M12 | 123 | 144 | 30 | 30 | 3 | M8 | 2300 |

| 491986 | 33148085 | 79-85 | M10/M12 | 130 | 152 | 30 | 30 | 3 | M8 | 2300 |

| 491987 | 33148092 | 86-92 | M10/M12 | 136 | 159 | 30 | 30 | 3 | M8 | 2300 |

| 491988 | 33148109 | 101-109 | M10/M12 | 154 | 175 | 30 | 30 | 3 | M8 | 2300 |

| 491989 | 33148116 | 108-116 | M10/M12 | 160 | 182 | 30 | 30 | 3 | M8 | 2300 |

| 491990 | 33148133 | 125-133 | M10/M12 | 178 | 200 | 30 | 30 | 3 | M8 | 2300 |

| 491991 | 33148140 | 132-140 | M10/M12 | 184 | 207 | 30 | 30 | 3 | M8 | 2300 |

| 491992 | 33148169 | 159-169 | M10/M12 | 223 | 254 | 38 | 38 | 4 | M10 | 3800 |

| 491993 | 33148188 | 178-188 | M10/M12 | 242 | 274 | 38 | 38 | 4 | M10 | 3800 |

| 491994 | 33148204 | 194-204 | M10/M12 | 258 | 290 | 38 | 38 | 4 | M10 | 3800 |

| 491995 | 33148213 | 203-213 | M10/M12 | 267 | 299 | 38 | 38 | 4 | M10 | 3800 |

| 491996 | 33148227 | 217-227 | M10/M12 | 282 | 322 | 38 | 38 | 4 | M12 | 3800 |

| 491997 | 33168169 | 159-169 | M16 | 220 | 254 | 40 | 38 | 4 | M10 | 3800 |

| 491998 | 33168188 | 178-188 | M16 | 239 | 274 | 40 | 38 | 4 | M10 | 3800 |

| 491999 | 33168204 | 194-204 | M16 | 255 | 290 | 40 | 38 | 4 | M10 | 3800 |

| 492000 | 33168213 | 203-213 | M16 | 264 | 299 | 40 | 38 | 4 | M10 | 3800 |

| 492001 | 33168227 | 217-227 | M16 | 278 | 322 | 40 | 38 | 4 | M12 | 3800 |

| 492002 | 33168250 | 240-250 | M16 | 289 | 345 | 40 | 38 | 4 | M12 | 3800 |

| 492003 | 33168275 | 265-275 | M16 | 327 | 367 | 50 | 48 | 5 | M12 | 9200 |

| 492005 | 33168325 | 315-325 | M16 | 374 | 414 | 50 | 48 | 5 | M12 | 9200 |

| 492006 | 33168364 | 354-364 | M16 | 412 | 453 | 50 | 48 | 5 | M12 | 9200 |

| 492007 | 33168408 | 398-408 | M16 | 444 | 498 | 50 | 48 | 5 | M12 | 9200 |

| 492008 | 33168458 | 448-458 | M16 | 494 | 548 | 50 | 48 | 5 | M12 | 9200 |

| 492009 | 33168509 | 499-509 | M16 | 545 | 599 | 50 | 48 | 5 | M12 | 9200 |

All products are tested according to RAL-GZ 655/B Ø 15 - 227 also tested according to RAL-GZ 656.