PP Elbow 45

Technical Specification

- Material: Polypropylene block copolymer (PP-B)

- Fitting type: 45° plain elbow

- Pressure rating: 10 bar

- Operating temperature range: -20°C to 120°C

- Sizes available: 20mm to 160mm

- Colour: Beige grey (RAL 7032)

- Standards: DIN 16962 Parts 5/6/7/8/9/12, ISO 7279:1984, ISO 15494:2003 Type B

- Jointing method: Socket fusion welding

- Internal profile: Smooth bore

Description

This polypropylene 45° elbow fitting is designed to introduce a gentle change in direction within metric PP pipe systems, helping to guide flow with reduced turbulence compared to sharper bends. Manufactured from high heat stabilised PP-B material, it is suitable for pressure-rated applications involving corrosive fluids and elevated temperatures.

The 45° angle makes this fitting ideal for installations where smoother flow paths are preferred or where gradual directional changes help minimise stress within the system. When fusion welded, the elbow forms a continuous joint that delivers excellent mechanical strength and long-term leak resistance.

Polypropylene’s resistance to corrosion and chemical attack makes this fitting particularly effective in industrial environments where metal components would suffer from degradation. Its inherent flexibility also allows it to accommodate thermal expansion and minor movement without compromising joint integrity.

Key Features & Benefits

- 10 bar pressure rating: Suitable for pressure-rated polypropylene pipework systems

- 45° directional change: Provides a smoother flow transition than a right-angle bend

- PP-B construction: Block copolymer material improves impact resistance, especially at lower temperatures

- Wide operating temperature range: Performs reliably from -20°C up to 120°C in continuous service

- Fusion welded joint: Produces a strong, homogeneous connection with excellent chemical resistance

- Smooth bore interior: Helps reduce pressure loss and maintain efficient flow through the bend

- Corrosion resistant: Will not rust, scale or degrade when exposed to aggressive media

- Lightweight fitting: Easier handling and faster installation compared to metal alternatives

- Industrial suitability: Commonly used in chemical processing, laboratories, water treatment, food production and manufacturing systems

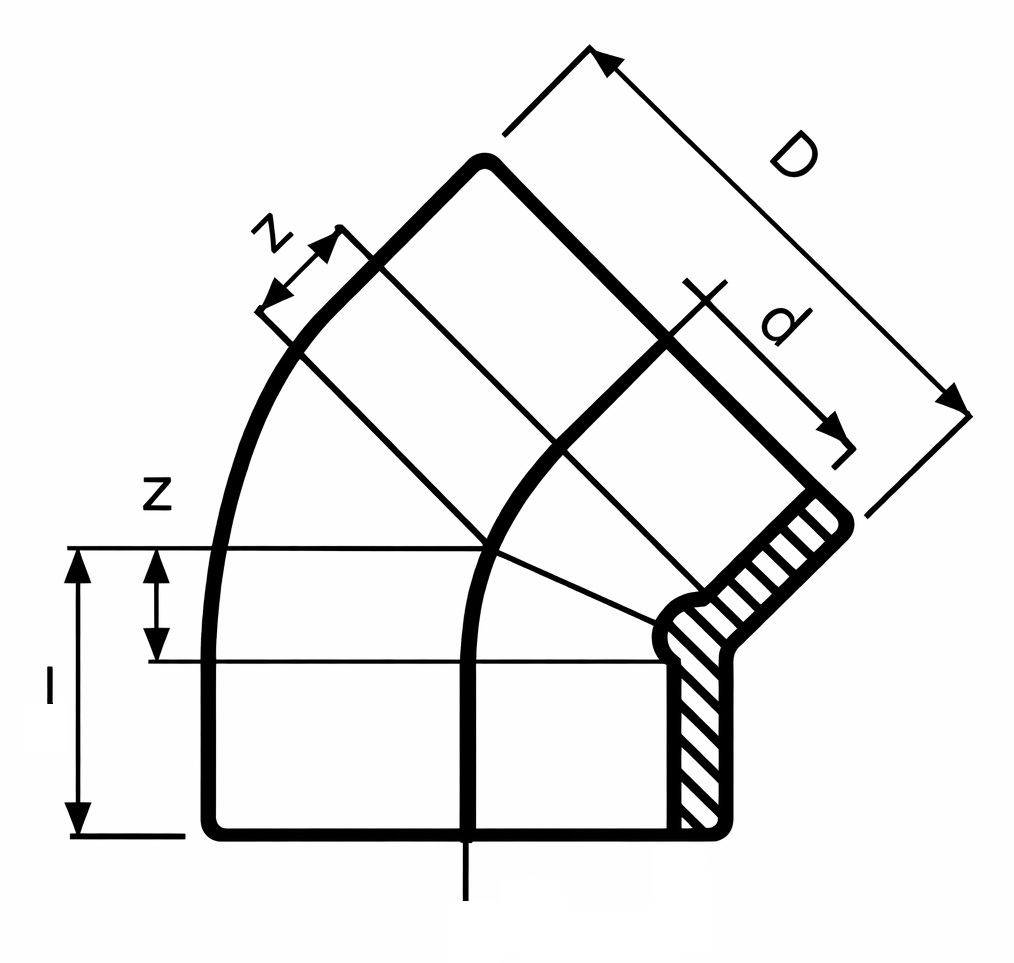

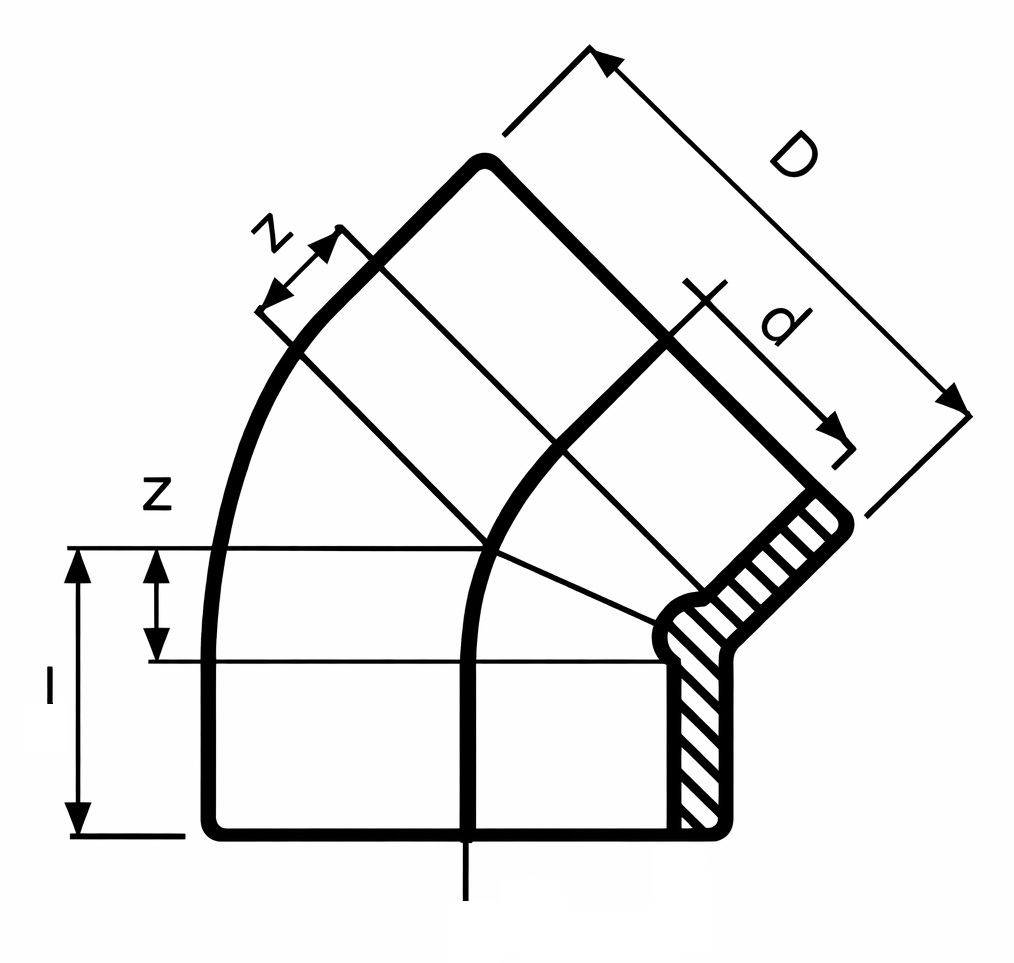

| Product Code | d (mm) | D (mm) | I (mm) | Z (mm) | Pressure Rating (bar) |

| 355819 | 20 | 27 | 22 | 8 | 10 |

| 355820 | 25 | 34 | 26 | 10 | 10 |

| 355821 | 32 | 41 | 30 | 12 | 10 |

| 355822 | 40 | 52 | 33 | 12 | 10 |

| 355823 | 50 | 61 | 38 | 15 | 10 |

| 355824 | 63 | 77 | 44 | 17 | 10 |

| 355825 | 75 | 91 | 50 | 20 | 10 |

| 355826 | 90 | 110 | 61 | 26 | 10 |

| 355827 | 110 | 134 | 71 | 30 | 10 |

| 355828 | 160 | 192 | 110 | 64 | 10 |