Fernco Wall Mounted Flap Valve

Technical Specification

- Mounting: Wall-mounted (FV Series)

- Size Range: DN100 – DN1000

- Material: High-Density Polyethylene (HDPE) with 316 Stainless Steel components

- Seal: Integrated EPDM (BS EN 681-1:1996 compliant)

- Pressure Rating: Up to 7 mwc (metres water column)

- Cracking Head: From 22 mm to 48 mm (varies by size)

- Standards: Exceeds DIN 19569-4, BS7775, ISO 9001:2015

- Installation Kit: Includes A4 stainless steel bolts and chemical anchor capsules

- Max Temperature Range: -30°C to 130°C

- Recommended Max Temperature: 80°C (constant), 100°C Intermittent

Description

Designed to offer robust backflow protection, this HDPE wall-mounted flap valve provides a highly reliable and cost-effective solution for non-return drainage systems. Engineered for easy installation and exceptional durability, it helps prevent water ingress from external sources like rising floodwaters, estuaries, and tidal conditions. Manufactured from high-density polyethylene, the valve resists corrosion and environmental degradation, delivering long-term performance with minimal maintenance. Suitable for pipe sizes from DN100 to DN1000, it incorporates an EPDM co-extrusion seal for a watertight fit, removing the need for tapes or grouts during installation.

Key Features

- Prevents backflow and protects against flood risks

- Manufactured from corrosion-resistant HDPE

- Lightweight construction for safer, faster installation

- EPDM co-extrusion seal for leak-free performance

- Requires no additional sealing materials

- Up to 60-year life expectancy with proper maintenance

- Wall-mounted design – ideal for surface installations

- Resistant to UV, chemicals, impact, and marine exposure

- Secure and tamper-proof due to no scrap value of materials

- Fully recyclable and environmentally safe

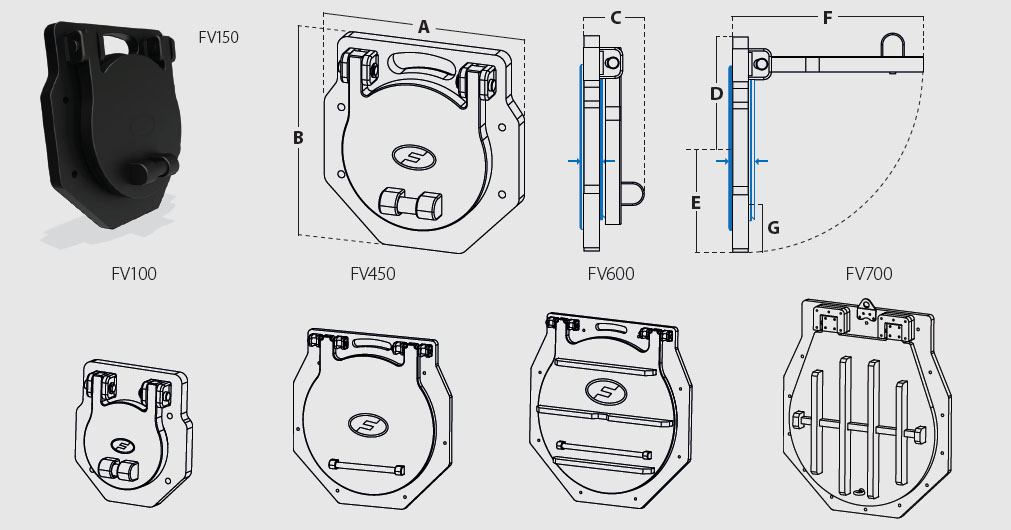

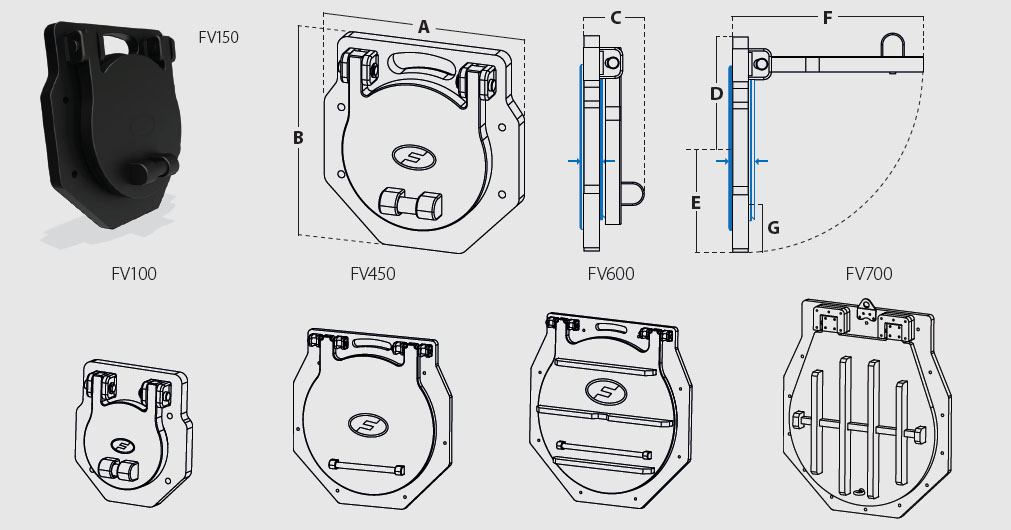

Dimensions & Design

| SKU | Fernco Code | DN | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | Mounting Hole PCD (mm) | Pressure | Weight (kg) |

| 489606 | FV100 | 100 | 212 | 235 | 79 | 129 | 106 | 208 | 56 | 183 | 7 | 1.29 |

| 489607 | FV125 | 125 | 254 | 268 | 79 | 142 | 127 | 233 | 65 | 225 | 7 | 1.68 |

| 489608 | FV150 | 150 | 274 | 291 | 79 | 154 | 137 | 248 | 62 | 240 | 7 | 1.89 |

| 489609 | FV200 | 200 | 341 | 349 | 79 | 179 | 170 | 298 | 70 | 321 | 7 | 2.72 |

| 489610 | FV225 | 225 | 351 | 367 | 79 | 191 | 176 | 323 | 64 | 315 | 7 | 2.96 |

| 489611 | FV250 | 250 | 379 | 392 | 79 | 202 | 190 | 346 | 65 | 350 | 7 | 3.37 |

| 489612 | FV300 | 300 | 429 | 442 | 79 | 228 | 214 | 397 | 64 | 400 | 7 | 4.23 |

| 489613 | FV350 | 350 | 499 | 517 | 79 | 268 | 249 | 472 | 74 | 460 | 7 | 5.69 |

| 489614 | FV400 | 400 | 544 | 565 | 79 | 293 | 272 | 522 | 72 | 515 | 7 | 6.69 |

| 489615 | FV450 | 450 | 594 | 615 | 79 | 318 | 297 | 572 | 72 | 565 | 7 | 7.85 |

| 489616 | FV500 | 500 | 649 | 667 | 99* | 343 | 324 | 622 | 74 | 620 | 7 | 10.07 |

| 489617 | FV600 | 600 | 754 | 770 | 99* | 393 | 377 | 722 | 77 | 725 | 7 | 13.55 |

| 489618 | FV700 | 700 | 895 | 1080** | 134 | 632** | 448 | 961 | 98 | 850 | 7 | 37.3 |

| 489619 | FV800 | 800 | 995 | 1180** | 134 | 682** | 498 | 1061 | 98 | 950 | 7 | 44.2 |

| 489620 | FV900 | 900 | 1095 | 1280** | 134 | 732** | 548 | 1161 | 98 | 1050 | 7 | 51.6 |

| 489621 | FV1000 | 1000 | 1195 | 1380** | 134 | 782** | 598 | 1261 | 98 | 1150 | 7 | 59.6 |

*Dimension taken from the back of the wall plate to front plate strengthening ribs.

**These values are taken from the top of the lifting bracket.

Mounting Set (Included)

The Mounting Sets include:

- M8 capsules & fixings for DN100-300 sizes or M12 capsules & fixings for DN400 sizes and larger

- Chemical resin capsules;

- Stainless Steel 1.4401 (316) anchor fixings;

Installation Guide For Fernco Wall Mounted Flap Valve

Important: Ensure the pipe end is flat and the wall surface is structurally sound and clean. The flap valve must be mounted with the hinge positioned at 12 o’clock.

Tools & Materials Required

- Drill with appropriate masonry bit (M8 bolts require 10mm bit; M12 bolts require 14mm)

- Chemical resin capsules (included with mounting set)

- Stainless steel A4 (316) bolts and washers (included)

- Torque wrench

- Spirit level

- PPE (gloves, goggles, etc.)

Mounting Set Contents (per size range)

- DN100–300: M8 capsules and bolts

- DN400 and above: M12 capsules and bolts

Step-by-Step Instructions

- Positioning - Hold the flap valve against the wall at the desired installation point, with the hinge at the top (12 o’clock). Use a spirit level to ensure correct alignment.

- Marking - Mark the drill points through the pre-formed mounting holes on the backplate.

- Drilling - Remove the valve and drill into the wall using the appropriate drill bit. Drill to the recommended depth (80mm for M8, 100mm for M12).

- Hole Preparation - Clean all dust and debris from the holes and the wall surface to ensure a secure bond with the resin capsules.

- Chemical Anchoring - Insert the supplied resin capsules into each drilled hole.

- Bolt Fixing - Insert bolts into the holes and drive them through the chemical capsules using a drill until they reach full depth.

- Curing - Allow the chemical resin to cure according to ambient temperature: e.g. 20 minutes at 6–10°C, 5 minutes at 21–30°C (Refer to full cure time table for varied temperatures)

- Final Mounting - Position the flap valve over the protruding bolts, ensuring correct alignment. Fit washers and nuts, then tighten to the recommended torque:

- M8 bolts: 4 Nm

- M12 bolts: 8 Nm

Post-Installation Checks

- Verify the flap swings freely and closes fully against the seal.

- Ensure no gaps exist between the backplate and wall.

- Check all bolts are securely torqued and cured.

Downloads