Fernco Spigot Mounted Flap Valve

Technical Specification

- Mounting: Spigot-mounted (FVS Series)

- Size Range: DN100 to DN630

- Material: High-Density Polyethylene (HDPE), with 316 Stainless Steel hardware

- Spigot Connection: Suitable for internal pipe fit or external coupling

- Seal: EPDM sealing tape or integrated bush (size dependent)

- Pressure Rating: 7 mwc

- Cracking Head: Typically 7 mm water column

- Standards: Exceeds DIN 19569-4, ISO 9001:2015, and BS7775

- Installation Method:

- Option 1: Insertion into pipe with EPDM sealing tape

- Option 2: Coupling onto pipe using Fernco shear banded coupling

- Max Temperature Range: -30°C to 130°C

- Recommended Max Temperature: 80°C (constant), 100°C Intermittent

Description

This high-performance spigot-mounted flap valve is purpose-built to prevent reverse flow and flooding within drainage and sewerage systems. Designed for direct connection to pipelines, it features a robust HDPE construction that resists corrosion and impact while remaining lightweight for ease of handling. The spigot design ensures compatibility with a range of pipe diameters, either via insertion or with a Fernco shear banded coupling for a secure, watertight fit. Ideal for new installations or retrofit applications, the valve acts as a dependable non-return solution in systems exposed to tidal surges, heavy rainfall, or high water tables.

Key Features

- Reliable backflow prevention for pipelines

- Direct spigot connection simplifies installation

- Options for insertion or coupling-based fixing

- Manufactured from corrosion-resistant HDPE

- Lightweight yet impact-resistant for safe handling

- EPDM sealing tape or integrated bush ensures leak-free fit

- No internal pipe obstruction – maintains optimal flow

- Resistant to UV, chemicals, and environmental degradation

- Operates under low cracking head pressures

- Fully recyclable and has no scrap value – theft deterrent

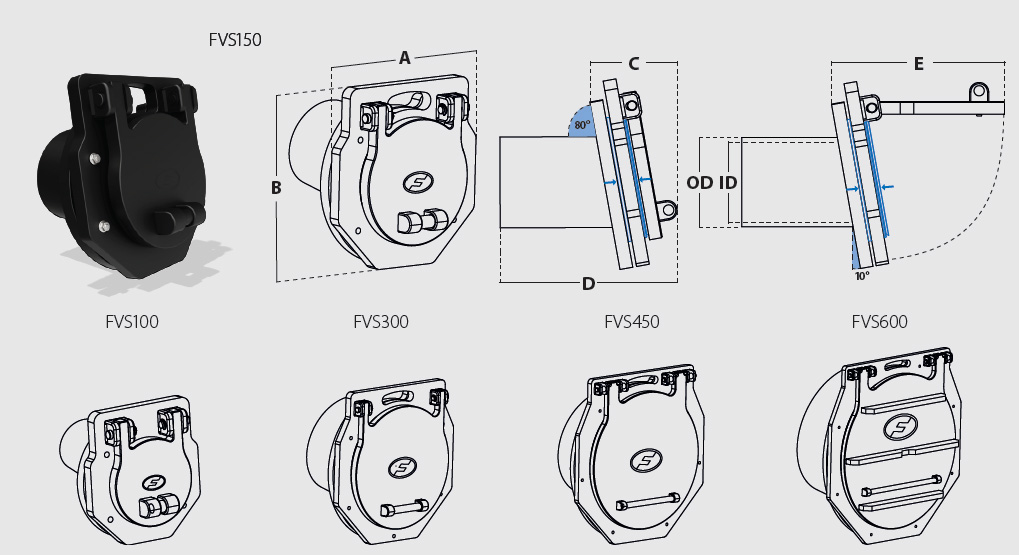

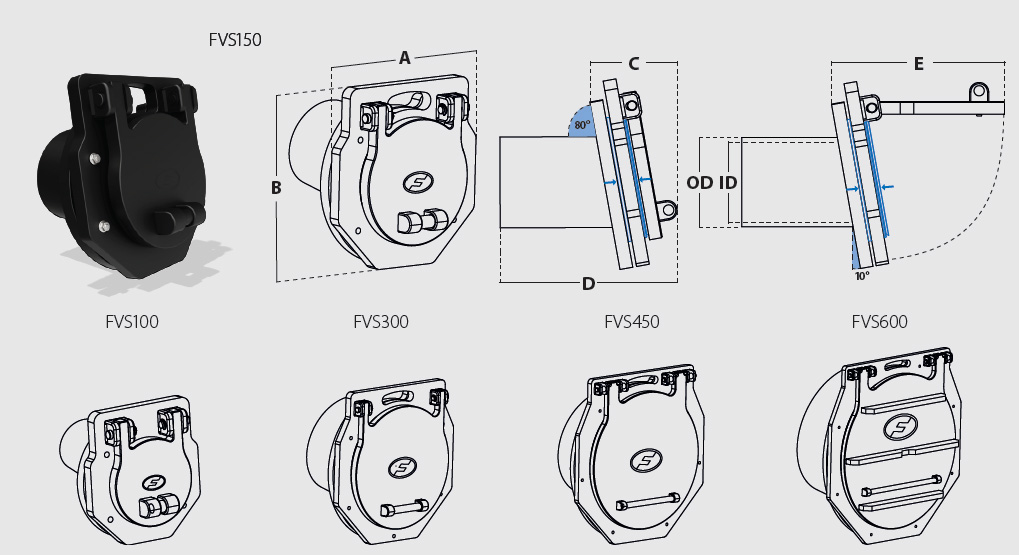

Dimensions & Design

| SKU | Fernco Code | DN | Spigot OD (mm) | Spigot ID (mm) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | Pressure (mwc) | Weight (kg) |

| 489622 | FVS100 | 100 | 90 | 83 | 212 | 235 | 125 | 264 | 234 | 7 | 2 |

| 489623 | FVS125 | 125 | 125 | 115 | 254 | 268 | 130 | 267 | 260 | 7 | 2.7 |

| 489624 | FVS150 | 150 | 140 | 123 | 254 | 268 | 130 | 271 | 260 | 7 | 2.9 |

| 489625 | FVS200 | 200 | 180 | 159 | 274 | 291 | 135 | 277 | 274 | 7 | 3.5 |

| 489626 | FVS225 | 225 | 200 | 184 | 340 | 349 | 144 | 284 | 327 | 7 | 4.6 |

| 489627 | FVS250 | 250 | 225 | 211 | 351 | 267 | 146 | 288 | 350 | 7 | 4.8 |

| 489628 | FVS300 | 300 | 280 | 263 | 379 | 392 | 151 | 296 | 376 | 7 | 5.6 |

| 489629 | FVS350 | 350 | 315 | 300 | 429 | 442 | 157 | 300 | 425 | 7 | 6.8 |

| 489630 | FVS400 | 400 | 355 | 333 | 499 | 517 | 167 | 309 | 490 | 7 | 10.3 |

| 489631 | FVS450 | 450 | 400 | 375 | 544 | 565 | 173 | 307 | 543 | 7 | 12.7 |

| 489632 | FVS500 | 500 | 450 | 422 | 594 | 615 | 178 | 369 | 597 | 7 | 14.7 |

| 489633 | FVS600 | 600 | 560 | 526 | 684 | 698 | 199* | 393* | 673 | 7 | 20 |

*Dimension taken from end of spigot to front plate strengthening ribs.

Installation Guide For Fernco Spigot Mounted Flap Valve

Important: Confirm the internal and external pipe diameters before installation to ensure correct sizing and seal fitment. The hinge must be positioned at the top (12 o’clock).

Tools & Materials Required

- Fernco shear banded coupling or EPDM sealing tape (size dependent)

- Marker pen or chalk

- Torque wrench

- Screwdriver or spanner (for clamp tightening)

- PPE (gloves, goggles, etc.)

Installation Method Options

The valve can be installed in one of two ways:

Option 1: Using Fernco Shear Banded Coupling (Recommended)

- Pipe Preparation: Ensure pipe end is flat, clean and free from debris. Mark the coupling width equally on both the spigot and the connecting pipe.

- Optional Bush Installation: If a sizing bush is required, slide it onto the spigot until flush with the marked line.

- Coupling Fitment: Slide the coupling over the spigot (or bush) and hand-tighten the central shear band.

- Alignment and Final Fit: Align the valve with the main pipe and ensure the hinge is at 12 o’clock. Tighten all clamp bands to the specified torque in sequence, starting from the centre.

Option 2: Insertion Using EPDM Sealing Tape

- Pipe Preparation: Ensure internal surface of the host pipe is clean and smooth. Confirm that the flap valve’s spigot will insert fully without obstruction.

- Apply Sealing Tape: Wrap the self-adhesive EPDM tape around the valve’s spigot to create a 5mm oversized diameter relative to the pipe’s internal diameter.

- Valve Insertion: Gently insert the spigot into the pipe until the backplate is flush. Ensure the hinge is positioned at the top (12 o’clock).

Post-Installation Checks

- Ensure the valve flap opens freely and closes flush against the seal.

- Check for secure, even seating around the spigot.

- If using a coupling, recheck clamp band tightness after 24 hours.

Downloads