Fernco Wall Mounted Tidal Flap Valve

Technical Specification

- Mounting: Wall-mounted (Tidal variant – FVT Series)

- Inclination: 10° for self-sealing in tidal flow conditions

- Size Range: DN100 to DN600 (larger sizes available on request)

- Material: HDPE body with 316 Stainless Steel components

- Seal: EPDM co-extrusion (BS EN 681-1:1996 compliant)

- Pressure Rating: 7 mwc

- Cracking Head: Typically 50–76 mm water column depending on size

- Standards: Exceeds DIN 19569-4, BS7775, ISO 9001:2015

- Mounting Kit: Includes stainless steel bolts and chemical anchor capsules

- Max Temperature Range: -30°C to 130°C

- Recommended Max Temperature: 80°C (constant), 100°C Intermittent

Description

Engineered specifically for tidal and coastal environments, this wall-mounted tidal flap valve delivers reliable non-return protection in drainage systems where water flow is affected by tidal backpressure or sloping pipework. With a 10° inclined flap mechanism, it ensures the valve remains closed under variable hydraulic conditions without relying on external pressure. The valve is constructed from high-density polyethylene (HDPE) and features a co-extruded EPDM seal, providing excellent resistance to corrosion, UV exposure, and chemical attack. Lightweight and easy to install, it offers long-term durability and low maintenance for applications prone to backflow and flooding.

Key Features

- 10° inclined flap for secure closing in tidal and sloped systems

- Designed to prevent backflow in coastal, estuarial and tidal locations

- Manufactured from corrosion-resistant HDPE for long-term durability

- Integrated EPDM seal eliminates need for separate sealing materials

- Lightweight construction enables safer and faster installation

- Requires low cracking head for reliable operation

- Resistant to UV degradation and environmental impact

- Tamper-proof design with no scrap value to deter theft

- Fully recyclable and compliant with relevant quality standards

- Easy to retrofit on existing flat wall structures

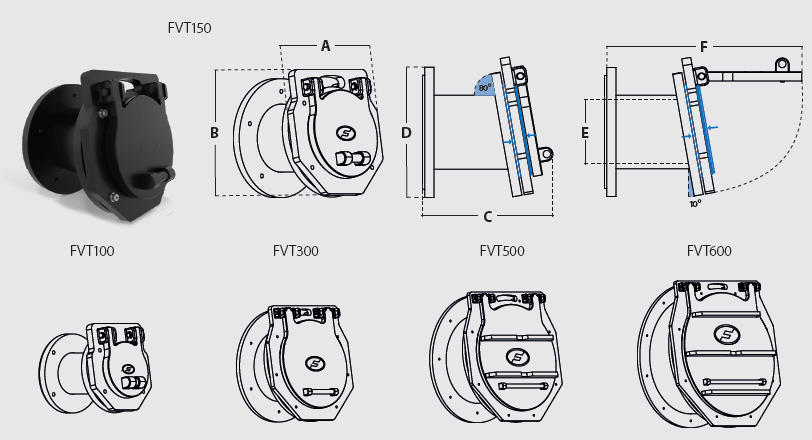

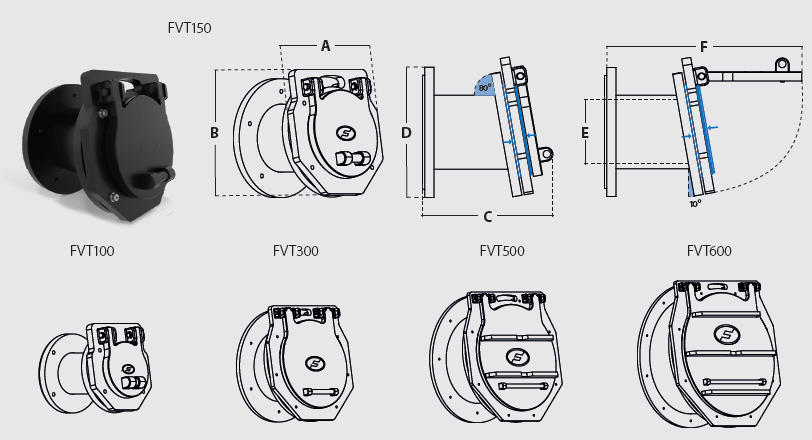

Dimensions & Design

| SKU | Fernco Code | DN | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | Mounting Hole PCD (mm) | Pressure (mwc) | Weight (kg) |

| 489634 | FVT100 | 100 | 212 | 235 | 267 | 212 | 102 | 376 | 183 | 7 | 2.6 |

| 489635 | FVT150 | 150 | 274 | 291 | 279 | 260 | 148 | 419 | 221 | 7 | 3.8 |

| 489636 | FVT200 | 200 | 351 | 267 | 288 | 340 | 211 | 493 | 283 | 7 | 6.3 |

| 489637 | FVT225 | 225 | 379 | 392 | 288 | 370 | 235 | 517 | 311 | 7 | 6.8 |

| 489638 | FVT250 | 250 | 379 | 392 | 296 | 385 | 263 | 521 | 333 | 7 | 6.8 |

| 489639 | FVT300 | 300 | 429 | 442 | 300 | 450 | 300 | 567 | 383 | 7 | 8.5 |

| 489640 | FVT400 | 400 | 544 | 565 | 367 | 595 | 422 | 788 | 523 | 7 | 17.2 |

| 489641 | FVT450 | 450 | - | - | - | - | - | - | - | - | - |

| 489642 | FVT500 | 500 | 685 | 698 | 393* | 695 | 526 | 868 | 628 | 7 | 23.6 |

| 489643 | FVT600 | 600 | 754 | 770 | 405* | 780 | 591 | 930 | 705 | 7 | 28.8 |

*Dimension taken from the back of the wall plate to front plate rib.

Mounting Set (Included)

The Mounting Sets include:

- M8 capsules & fixings for DN100-300 sizes or M12 capsules & fixings for DN400 sizes and larger

- Chemical resin capsules;

- Stainless Steel 1.4401 (316) anchor fixings;

Installation Guide For Fernco Wall Mounted Tidal Flap Valve

Important: This valve is specifically designed for tidal or sloped installations and must be mounted with the hinge at the 12 o’clock position. The 10° inclined flap enables proper closure even under low or reversing pressure conditions.

Tools & Materials Required

- Drill with appropriate masonry bit (M8 for DN100–DN400, M12 for DN500–DN600)

- Chemical resin capsules (included with mounting set)

- Stainless steel A4 (316) bolts, washers, and nuts (included)

- Torque wrench

- Spirit level

- PPE (gloves, goggles, etc.)

Mounting Set Contents (per size range)

- DN100: 4x M8 bolts

- DN150–DN250: 5x or 6x M8 bolts

- DN300–DN400: 8x M8 bolts

- DN500–DN600: 10x M8 bolts

Step-by-Step Instructions

- Position the Valve: Place the valve against the wall where it will be mounted. Ensure the flap hinge is at the 12 o’clock position. Check that the inclined flap is angled downward and outward for optimal tidal performance.

- Mark Mounting Holes: Use the mounting plate as a template to mark drill points. Confirm alignment with a spirit level.

- Drill Mounting Holes: Remove the valve and drill holes at the marked locations using the appropriate drill bit:

- M8 bolts: 10mm bit, 80mm depth

- M12 bolts: 14mm bit, 100mm depth

- Clean & Prepare: Remove all dust and debris from drilled holes and wall surface.

- Install Resin Capsules: Insert the chemical resin capsules into each drilled hole.

- Fix Anchor Bolts: Drive stainless steel bolts into each hole and allow resin to cure. Cure Time Example: 20 mins at 6–10°C, 5 mins at 21–30°C. Refer to resin curing chart for full temperature range.

- Mount the Valve: Place the valve over the installed bolts. Fit washers and nuts, then tighten to the following torque:

- M8 bolts: 4 Nm

- M12 bolts: 8 Nm

Post-Installation Checks

- Verify the flap opens freely and closes firmly at rest.

- Ensure valve is level and evenly secured to the wall.

- Inspect for visible gaps or misalignment.

Downloads