Prevost Industrial Anti-Static Air Hose Reel

Technical Specification

- Media Type: Compressed Air

- Hose Material: Anti-static Polyurethane

- Flow Rate: 800 L/min

- Hose Length Options: 12m

- Max Operating Pressure: 12 bar

- Operating Temperature: -15°C to 65°C

- Net Weight: 7.22kg

- Case Material: Galvanised steel with UV-resistant polyester coating

- Auto Rewind: System to retract the hose automatically

- Swivel Bracket: 180° pivot range

- Mounting Options: Wall or ceiling

- Adjustable Stop: Holds the hose at the desired length

- Inlet Hose: 1m length

- Anti Static: ATEX Approved

Description

This hose is engineered for environments where static charge must be controlled, and is fully ATEX‑compliant for safe use in potentially explosive atmospheres. Its anti‑static polyurethane construction ensures excellent flexibility, abrasion resistance, and long service life while maintaining electrical continuity. The design ensures compatibility with standard fittings and profiles, facilitating easy integration into existing systems. Despite its static-dissipating features, it retains the durability and flexibility expected of premium polyurethane hoses.

What is ATEX Approval?

If a product is ATEX-approved, it has been tested and certified as safe for use in areas where flammable gases, vapours, mists, or combustible dusts may be present. ATEX stands for "ATmosphères EXplosibles", which is French for "explosive atmospheres".

ATEX has two main directives, these are:

-

Directive 1999/92/EC

- This directive covers the minimum requirements for protecting workers' health and safety when in explosive atmospheres

-

Directive 2014/34/EU

-

This directive covers the design and manufacture of equipment and protective systems intended for use in explosive atmospheres. Typically, this applies to machinery, electrical devices, and protective equipment.

-

Also known as "ATEX 114" and "The ATEX Equipment Directive".

-

ATEX products are classified based on their safety and proximity to explosive hazards. They are divided into zones:

- Zone 0/20: Product is rated for continuous presence of explosive atmosphere

- Zone 1/21: Product is rated for likely presence during normal operation.

- Zone 2/22: Product is rated for rare or short-term presence.

Zones 0, 1 and 2 refer to Gases, while zones 20, 21 and 22 refer to Dusts.

Where does ATEX Approval Matter?

ATEX approved products must be used in potentially explosive environments, and these are far more common than you may think. Some of these places are:

- Petrol stations/forecourts

- Oil and gas facilities

- Chemical plants/refineries

- Fuel storage depots

- Paint spray booths and mixing rooms

- Dry cleaning works

- Hydrogen generation and storage

- Coal handling and storage

- Metal powder processing

- Powder coating facilities

- Battery charging/maintenance rooms

- Aviation hangars and refuelling stations

- Aerosol and solvent production plants

- Automotive repair workshops

- Waste transfer stations

- Flour mills and grain handling stations

- Sugar processing plants/refineries

- Woodworking shops

- Cement production

- Plastics processing

Key Features

- Safety Spring Mechanism: Provides a controlled hose return, preventing rapid retraction that could cause injury or damage.

- Anti-Static Hose: ATEX-rated design to ensure safety in potentially explosive environments

- Anti-Whiplash Coupling: Allows for the safe decompression and disconnection of pneumatic tools in a single movement, preventing hose whip and potential injuries.

- Quick Mounting System: Facilitates easy installation with three possible hose orientations, ensuring adaptability to different workspaces.

- Locking System: Holds the hose at the desired length, allowing users to work comfortably without hose pullback.

- Anti-Twist Pipe Protectors: Prevents the hose from twisting, ensuring smooth operation and extending the hose's lifespan.

- Limit Switch: Enhances user control by limiting the hose retraction point.

- Galvanised Steel Housing: Features a UV-resistant polyester-based electrostatic powder coating that protects against corrosion and wear, ensuring durability even in harsh environments.

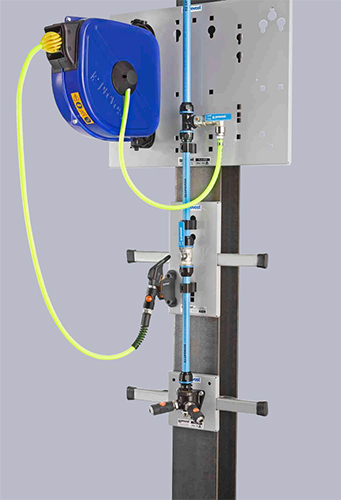

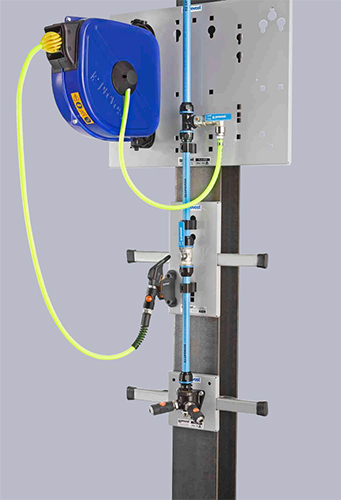

- 180-Degree Swivel Bracket: The reel can be mounted on walls or overhead structures, providing flexibility in installation and improving workspace organisation.

Quick Mounting System

The Prevost quick mounting system simplifies hose reel installation. The bracket detaches from the reel, allowing it to be fixed to the wall with ease. Once in place, the reel can be quickly mounted onto the bracket and secured with the quick-mounting clip, no awkward handling required.

Hose Positioning

The Prevost hose reel features an adjustable inlet that can be positioned in three different orientations, allowing flexibility to suit the installation. This design helps maintain a neat and organised setup while preventing sharp bends or kinks that could restrict flow.

Materials & Dimensions

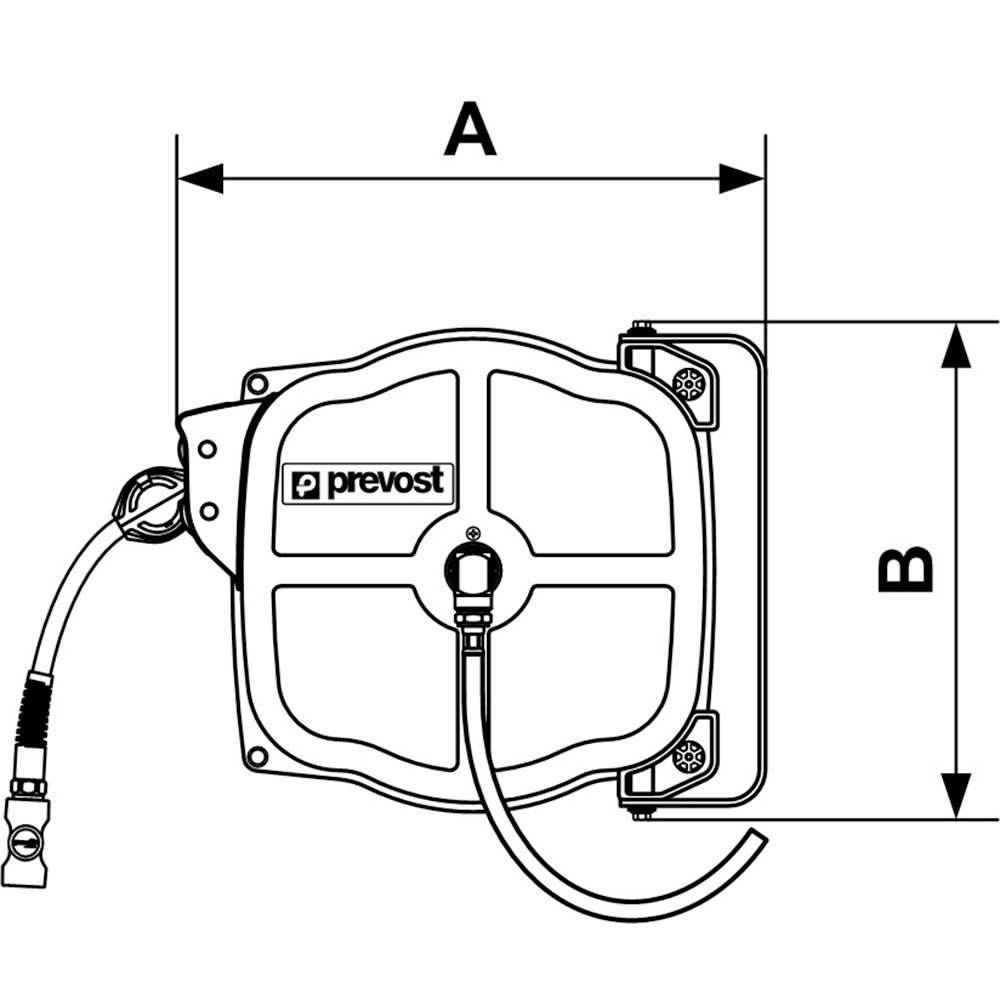

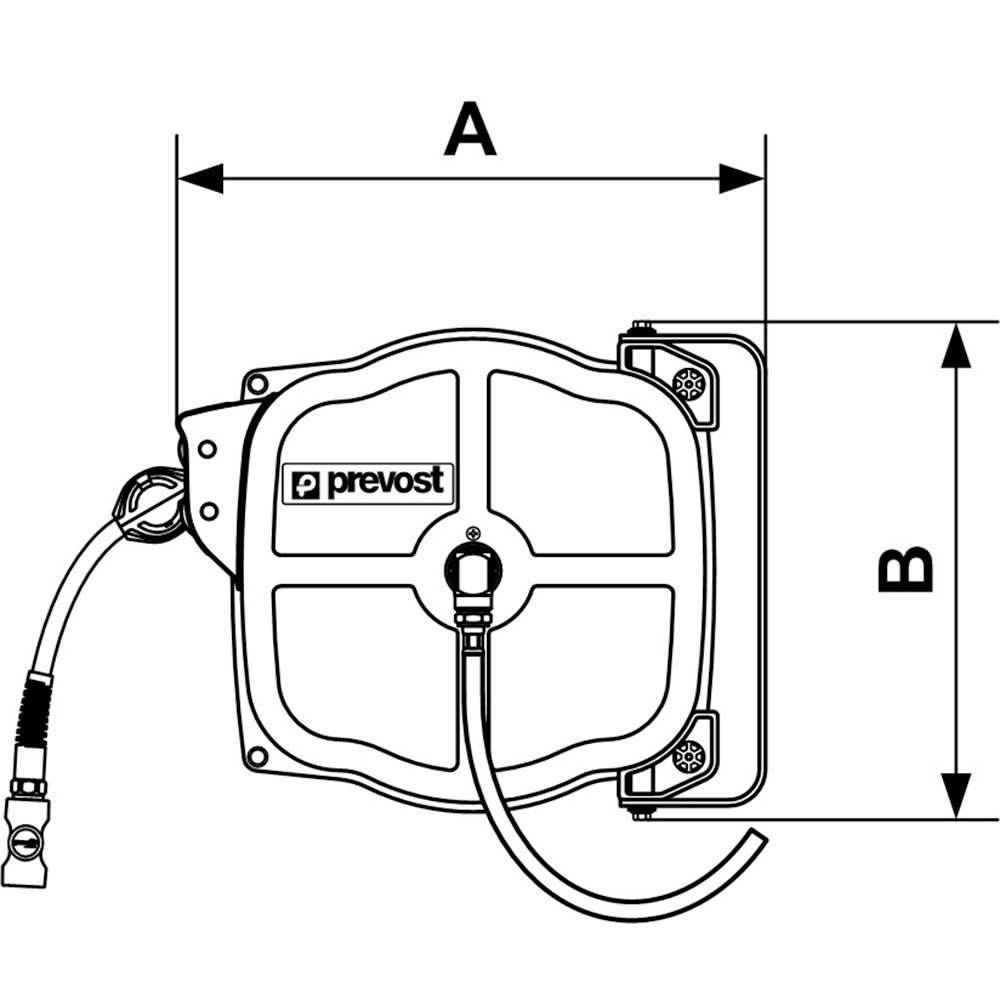

| Product Code | Prevost Code | ID/OD (mm) | Length (m) | Coupling | Flow Rate (l/min) | Weight (kg) | A (mm) | B (mm) |

| 407008 | DPFEX 1012ES | 10 x 14 | 12 | ESI 07 (Euro) | 800 | 7.22 | 377 | 317 |