ABS Full Face BS10 Table D/E

Technical Specification

- Material: Acrylonitrile butadiene styrene (ABS)

- Colour: Light grey

- Size range: 1/2 inch to 4 inch

- Connection type: Full face ABS flange drilled to BS 10:1962 Tables D and E

- Joining method: Solvent cement with ABS cleaner for bonding to pipe

- Approvals: WRAS approval 1703070 where applicable, BSI Kitemark KM60042

- Temperature range: -40°C to 60°C

- Standards: BS 10:1962 Tables D and E, BS 5392, BS 5391, EN 10226 1, DIN 2999, DIN DVS 2204 3

- Chemical resistance: Suitable for diluted inorganic acids, salts, animal fats, oils and organic acids, not compatible with petrol, alcohol, organic solvents or vegetable oils

- Applications: Creating flanged joints on ABS pipelines, connecting to valves, pumps, tanks and legacy BS10-compatible equipment

Description

This ABS full face flange is drilled to BS 10:1962 Tables D and E, making it suitable for installations that follow traditional UK flange standards or require compatibility with older equipment. Designed for use where a bolted connection is needed, the flange attaches to ABS pipe through solvent welding, forming a secure and long-lasting joint. Once fixed to the pipe, the flange can be paired with a corresponding drilled component and sealed using a gasket and appropriate bolting arrangement. Manufactured from high quality ABS, it offers excellent impact strength, corrosion resistance and dependable performance across its working temperature range. It is widely used in water treatment, processing, and industrial environments where a detachable flanged connection is required.

Key Features & Benefits

- BS10 D/E drilling: Compatible with legacy and modern systems using traditional UK flange tables

- Reliable flanged joint: Allows pipework to be bolted to valves, pumps or tank outlets

- Strong solvent weld connection: Creates a secure attachment to ABS pipe

- Durable ABS construction: Lightweight, corrosion resistant and impact tolerant

- Suitable for many diluted chemicals: Ideal for process and water treatment applications

- WRAS and Kitemark certified: Ensures high manufacturing and performance standards

- Easy system maintenance: Flanged joint can be unbolted for inspection or replacement

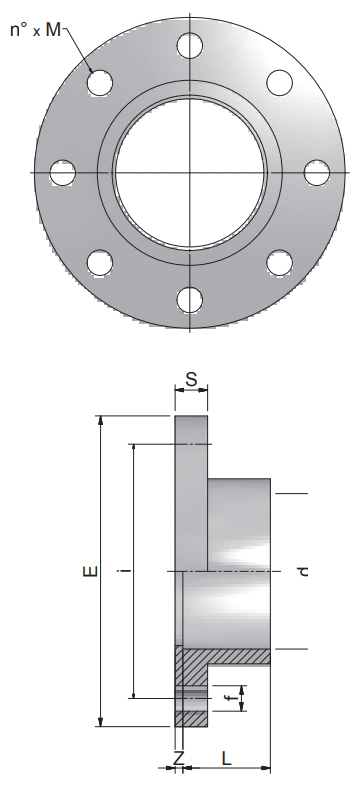

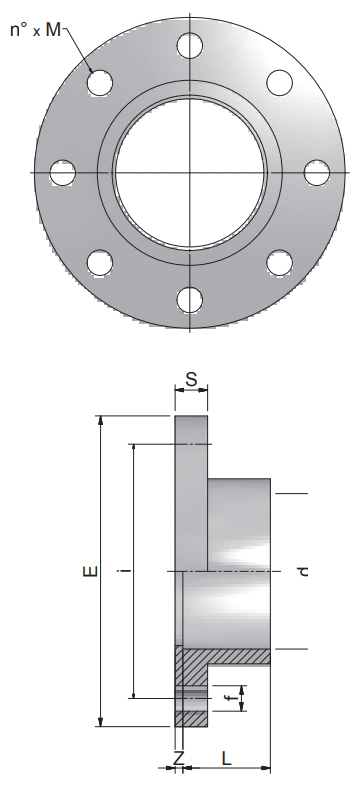

| SKU | Nominal Size / d (inch) | L (mm) | S (mm) | i (mm) | f (mm) | Z (mm) | E (mm) | n° x M |

| 359995 | 1/2 | - | - | - | - | - | - | - |

| 359996 | 3/4 | - | - | - | - | - | - | - |

| 353105 | 1 1/2 | 4.5 | 16 | 110 | 18 | 152 | 31 | 4 x M16 |

| 353106 | 2 | 4.5 | 20 | 125 | 18 | 165 | 38 | 4 x M16 |

| 353107 | 3 | 7 | 22 | 160 | 18 | 200 | 51 | 8 x M16 |

| 353108 | 4 | 8 | 23 | 180 | 18 | 220 | 61 | 8 x M16 |