Universal Coupling

Useful Information

Technical Specification

- Type: Universal Compression Coupling

- Connection Range: 15–21mm x 20mm - Up to 59–61mm x 63mm

- Material Composition:

- Body: Polypropylene

- Spacer: Polypropylene

- Split Ring: Acetal

- Seal: Nitrile rubber (NBR)

- Grip Teeth: Stainless steel

- Pressure Rating: 12.5 bar at 20°C

- Temperature Range: 0°C to +40°C (cold water use)

- Standards Compliance: WRAS approved for use in potable water systems

- Pipe Compatibility: MDPE, PVC, ABS, Copper, Stainless Steel, Galvanised Iron, Lead

- Included Components: Integrated pipe liner (Replacements Available)

Description

The Universal Compression Coupling is designed to connect MDPE pipe to a wide range of other pipe materials, including PVC, ABS, copper, stainless steel, galvanised iron, and lead. With a pre-assembled body and included pipe liner, this versatile fitting simplifies the joining process across mixed material systems. The UTC ends are equipped with stainless steel teeth to ensure a strong mechanical grip and excellent end-load resistance. Suitable for water supply and general low-pressure fluid systems, the coupling offers reliable sealing and quick installation without the need for specialist tools.

Key Features & Benefits

- Multi-Material Compatibility: Connects MDPE to various pipe types, including metal and plastic,c without the need for adaptors.

- Pre-Assembled for Convenience: Supplied ready to install—simply insert the pipe and tighten the nut.

- High Grip Strength: Stainless steel teeth provide strong end-load resistance, preventing pipe pull-out under pressure.

- Watertight Sealing: Compression system with nitrile rubber seals ensures long-lasting joint integrity.

- Quick and Easy Installation: Requires no special tools or heating—ideal for on-site repairs and system modifications.

- Built-In Pipe Liner: Supplied with an internal stiffener, ensuring pipe wall reinforcement and improved joint performance.

- Durable and Corrosion-Resistant: High-grade materials provide resistance to UV, mechanical stress, and chemical exposure.

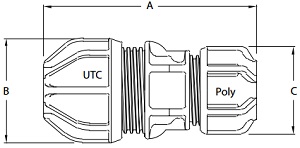

| Product Code | Supplier Code | A (mm) | B (mm) | C (mm) |

| 355030 | 1032 | 114 | 54 | 47 |

| 355031 | 1033 | 118 | 54 | 55 |

| 355032 | 1042 | 132 | 66 | 47 |

| 355033 | 1043 | 130 | 66 | 55 |

| 355034 | 1052 | 148 | 80 | 47 |

| 355035 | 1053 | 149 | 80 | 55 |

| 355036 | 1054 | 150 | 80 | 67 |

| 355037 | 1055 | 150 | 80 | 81 |

| 355038 | 1064 | 153 | 80 | 67 |

| 355039 | 1065 | 160 | 80 | 81 |

| 355040 | 1074 | 168 | 96 | 67 |

| 355041 | 1075 | 175 | 96 | 81 |

| 355042 | 1086 | 199 | 96 | 94 |

| 355043 | 1087 | 200 | 96 | 110 |

| 355044 | 1097 | 227 | 113 | 110 |